Uses

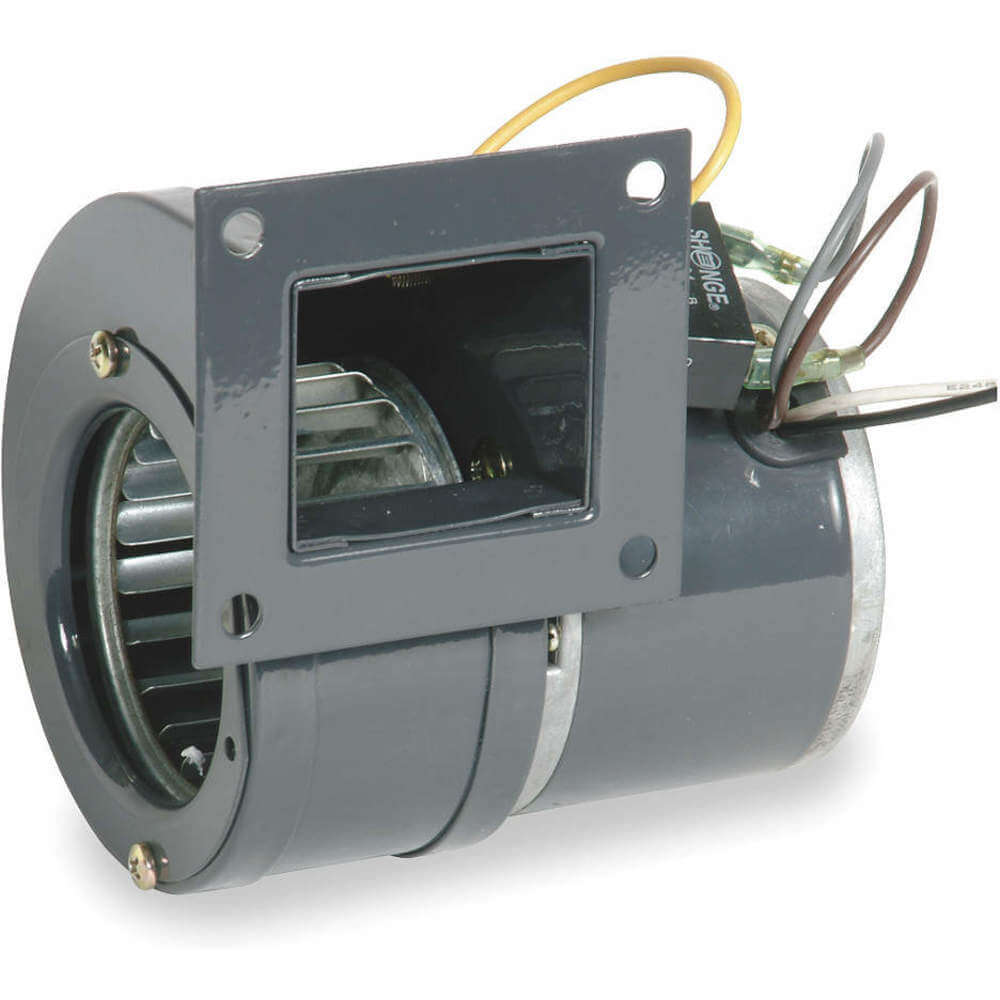

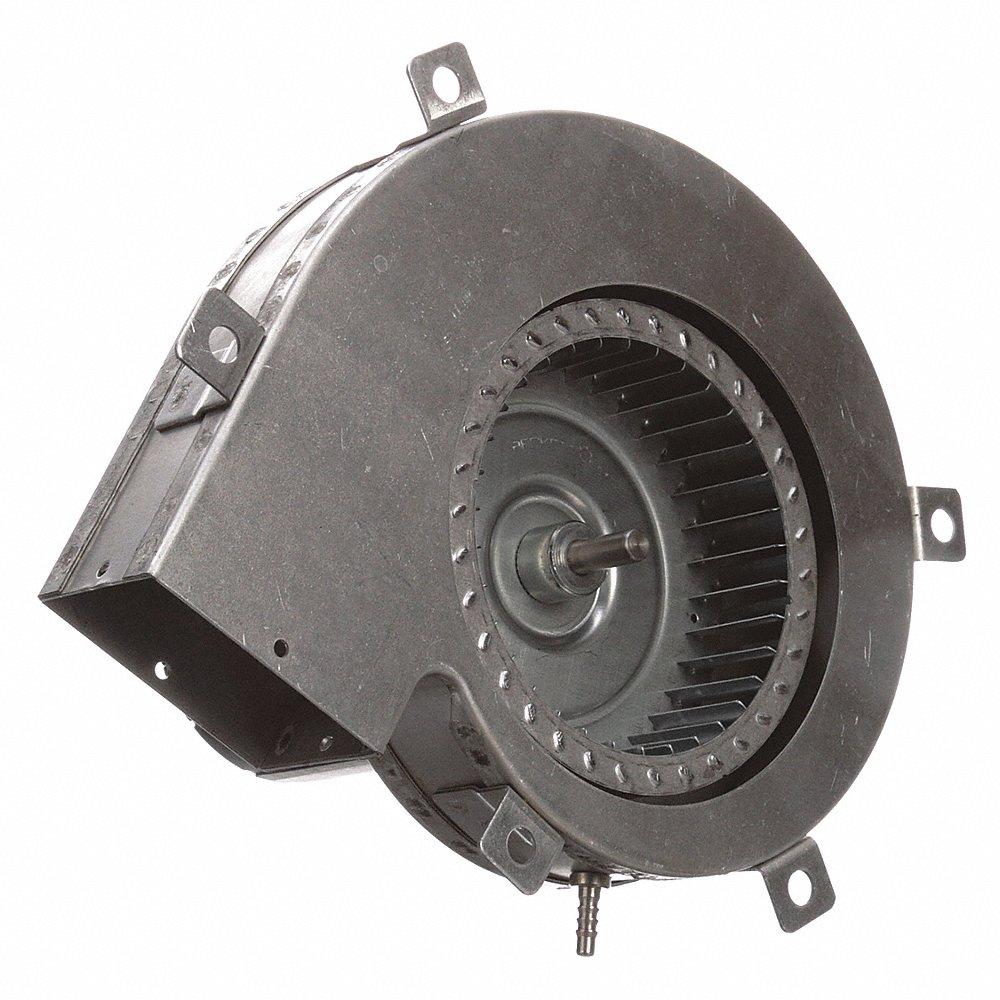

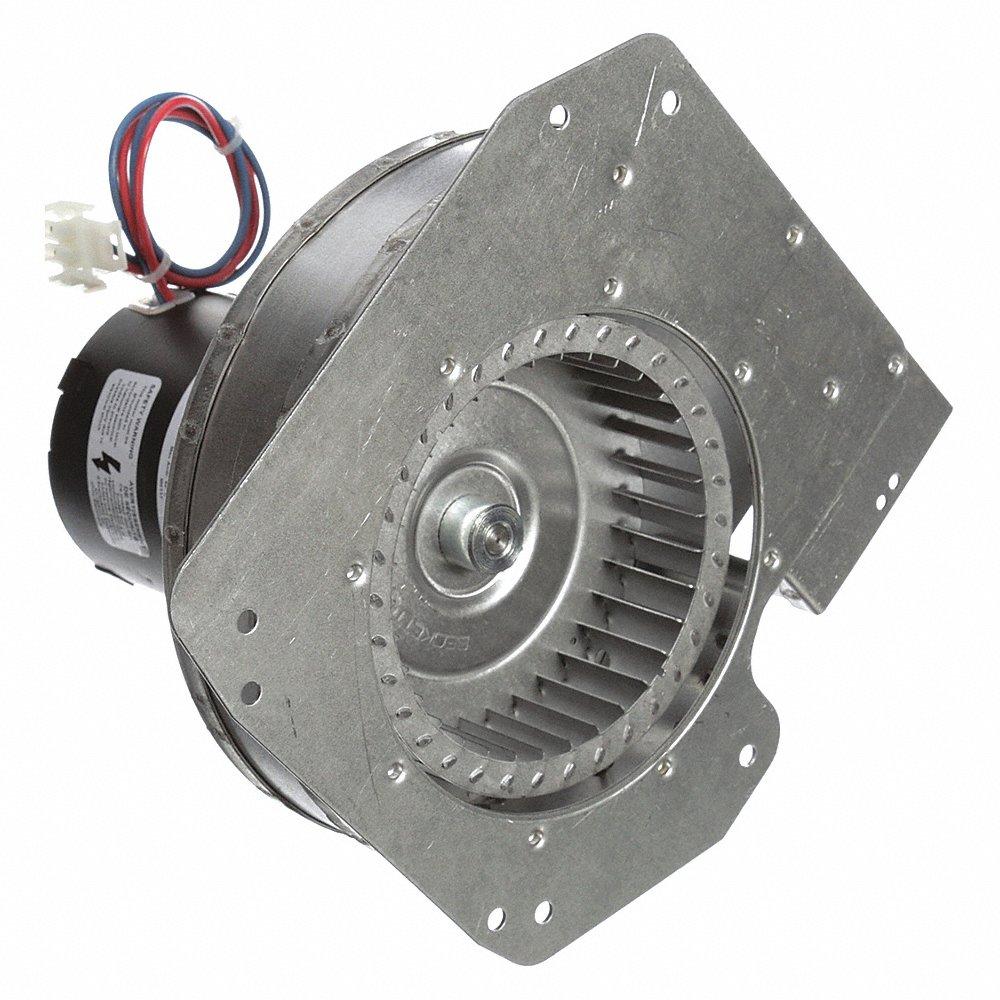

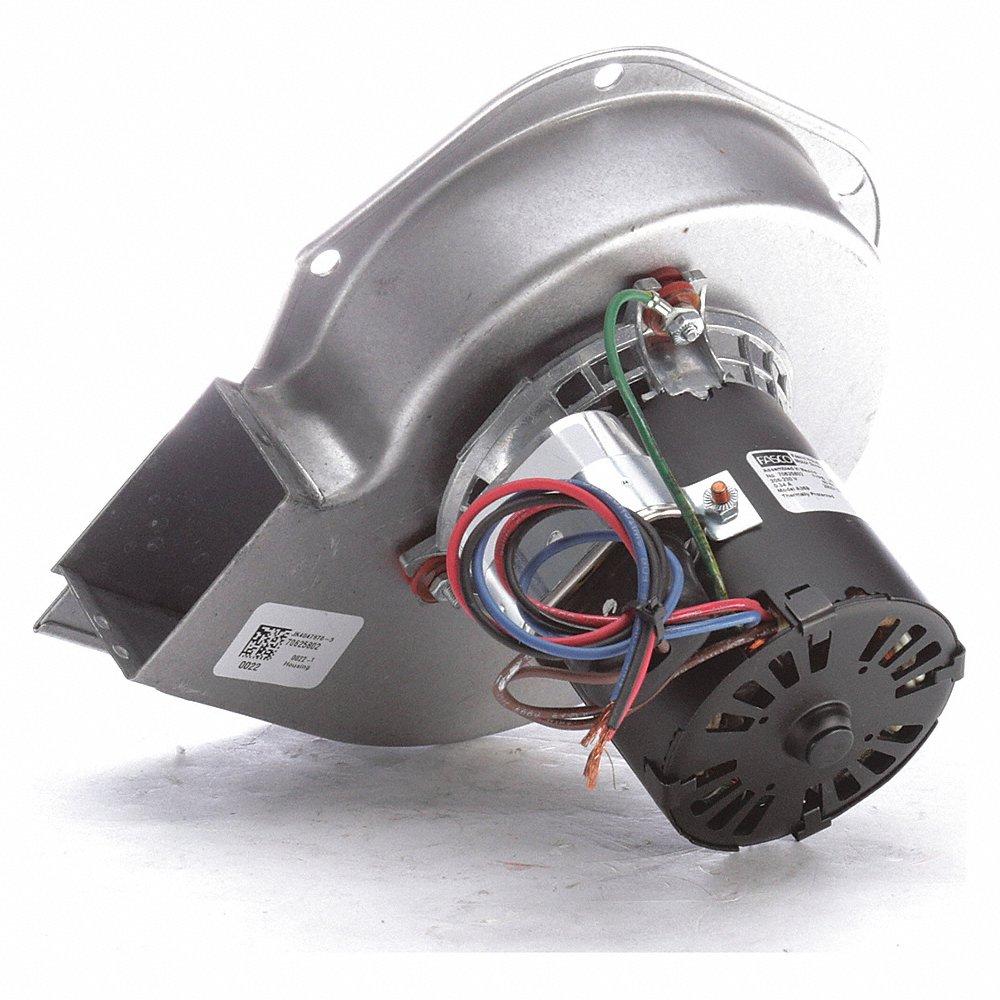

OEM specialty blowers are ideally used for replacing a faulty, old or worn out original equipment's blower. These OEM blowers can provide direct in-situ replacement of the blowers as they have the same physical footprint (shape & size) as the blower being replaced.

Frequently Asked Questions

What to do in case of specialty blower failure?

Assuming that the selected OEM blower is supplied with the correct power supply and is the correct choice for the desired airflow, the first thing to check is the status of the wiring connections. Motors should also be lubricated regularly for smooth operation. Users should also take care that they do not run the blowers in the opposite direction of the motor rotation as it leads to a shorter operating life of the blowers.

How can users select the right OEM specialty blowers for their needs?

First, the users should measure the electrical supply specifications required for powering their OEM blower. Depending upon the surface area of the space, the required airflow of the blower should also be calculated. The customers should take note of the construction, type of motor used and the ducting connections available before buying the unit.

What accessories are compatible with the Dayton OEM blowers?

Raptor Supplies can deliver a wide range of accessories that fit into these Dayton OEM blowers. Couplers are used to link these blowers with compatible ducts for airtight supply or discharge of air. They can also be fitted with outlet guards for preventing entry of contaminants & damage to the OEM blowers. We also supply replacement parts like motors, fan blades, mounting hardware and blower wheels for replacing faulty parts of the Dayton OEM blowers.

What variants of OEM blowers are available on Raptor Supplies?

Raptor Supplies offers various variants of OEM blowers, namely backward incline blowers, belt drive forward curve blowers and spark resistant blowers. The backward inclined blowers are designed to operate regardless of the static pressure applied, due to their overload protection facility. The belt drive forward curve blowers offer flexibility in terms of rotational speeds as compared to direct-drive blowers, as the motor is not directly connected with their fan or wheel's moving parts. Spark resistant blowers are used to ventilate commercial kitchens & other hazardous areas that have traces of flammable gases or volatile compounds.

£ GBPChange Country

£ GBPChange Country