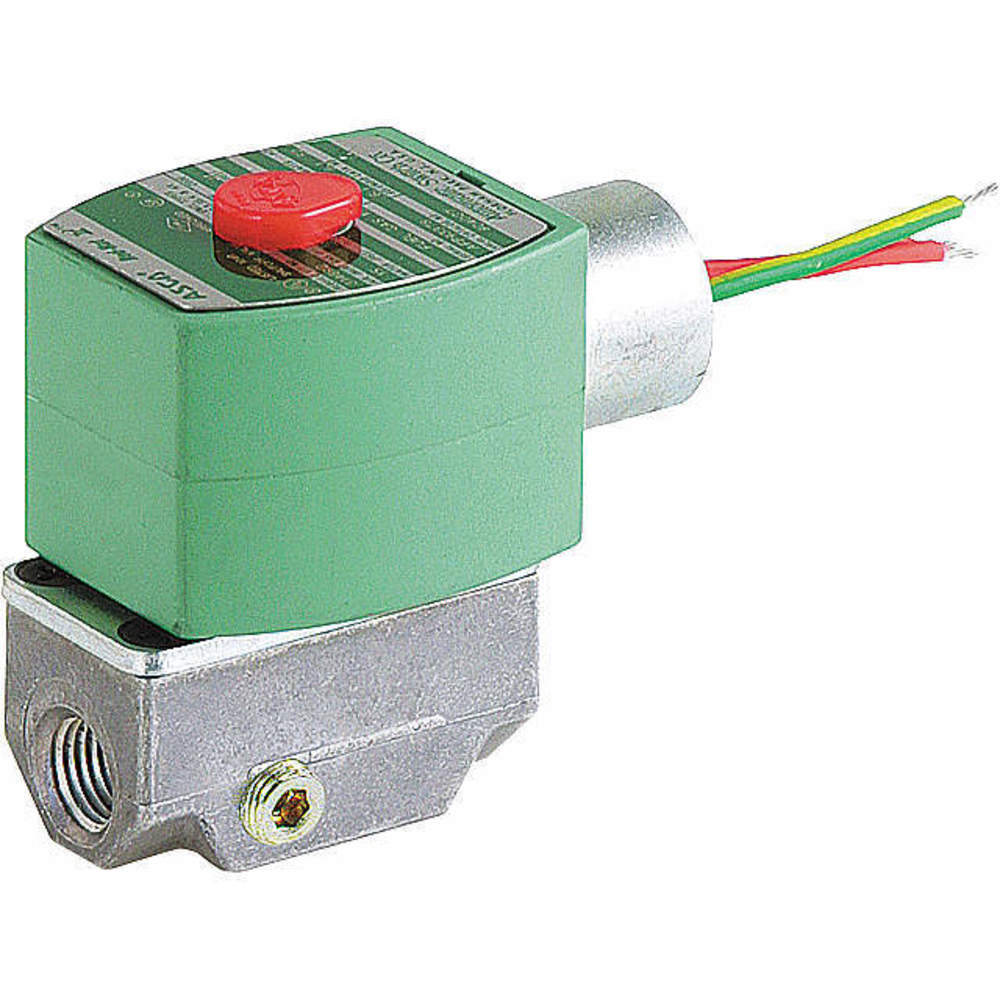

Body Material: Aluminum , Coil Insulation Class: F , Max. Fluid Temp.: 125 Degrees F , Min. Operating Pressure Differential: 0 psi , Seal Material: NBR , Valve Design: 2-Way/2-Position

Working Mechanism

- They operate based on the principle of electromagnetism. When an electrical current is applied to the coil (solenoid) surrounding the valve, it generates a magnetic field, which attracts a plunger or piston within the valve mechanism.

- This movement of the plunger or piston opens or closes the valve's main flow passage, allowing or blocking the flow of fuel or gas.

- The valve returns to its default position (open or closed) when the electrical current is removed, making solenoid valves efficient & reliable for regulating gas flow in response to electrical signals.

Features

- They feature aluminium construction, ensuring durability and resistance to corrosion.

- These valves have Class F coil insulation to allow them to operate effectively even in high-temperature environments.

- They can handle fluids with a maximum temperature of up to 125 degrees F.

- These valves have a minimal operating pressure differential requirement of 0 psi, ensuring efficient performance in various pressure conditions.

- They are equipped with NBR seals, enhancing their sealing capabilities.

- These valves can be configured as normally closed / normally open, providing precise control and flexibility for regulating fluid flow in industrial systems.

Frequently Asked Questions

How do I maintain these ASCO fuel gas solenoid valves?

- Implement regular inspections to detect signs of wear, corrosion or damage.

- Check for gas or fluid leaks in both the valve and its connections.

- Keep the test port clean and free from debris for accurate testing.

- Examine electrical connections for loose wires or damaged insulation.

- Verify the solenoid coil's integrity and secure attachment to the valve.

- Periodically conduct functional tests to ensure proper valve operation.

- Lubricate moving parts if recommended by the manufacturer.

- Replace worn-out or damaged components with manufacturer-recommended parts.

- Ensure the valve operates within its specified environmental conditions.

What safety precautions should I take while using these fuel gas solenoid valves?

- Ensure proper installation with secure connections, using appropriate tools and fittings.

- Inspect electrical connections for damage and follow electrical safety codes during installation and maintenance.

- Operate the valve within specified ambient temperature and environmental conditions to maintain safe performance.

- Verify compatibility with system pressure and flow requirements, using pressure regulators and relief valves when necessary.

- Implement routine maintenance as recommended, wearing appropriate personal protective equipment (PPE).

- Regularly check for gas or fluid leaks around the valve and use leak detection methods for safety.

What valve design does it feature?

This valve is designed as a 2-way / 2-position valve, providing precise control and flexibility for regulating fluid flow in industrial systems.

How does the test port benefit users?

The test port allows users to perform maintenance and diagnostic checks without disrupting the fuel supply, saving time and ensuring system reliability.

What are the factors to consider while choosing these ASCO fuel gas solenoid valves with test ports?

- Operating environment

- Flow requirements

- Pressure and fluid compatibility

- Electrical specifications

- Application type

- Heat output (BtuH)

- Dimensions and mounting

- Maintenance and serviceability

Change Country

Change Country