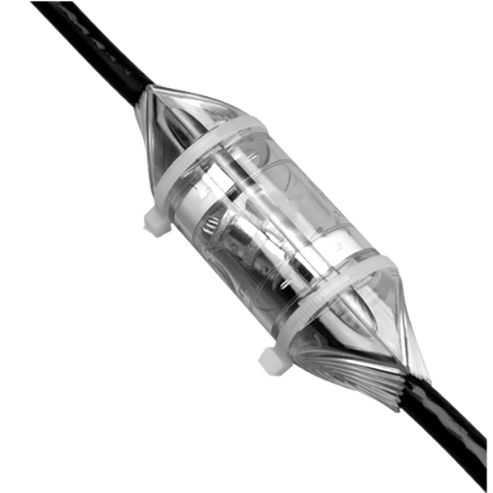

SCRULUG Terminals

These tin-plated, high-copper alloy terminals are used to connect a variety of cables to equipment pads or terminal blocks. They are particularly useful in light industrial applications. These terminals have a one-piece tongue and body design. The pressure bar balances the pressure across the conduc...