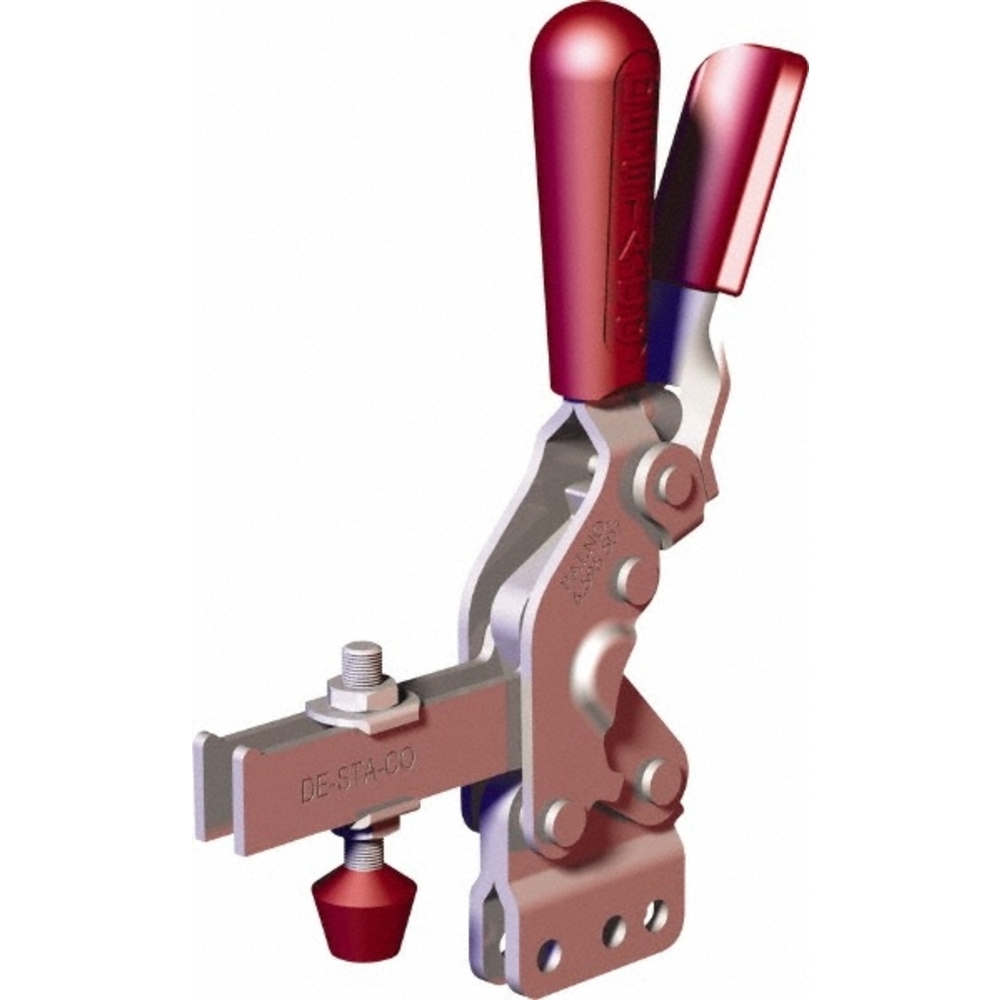

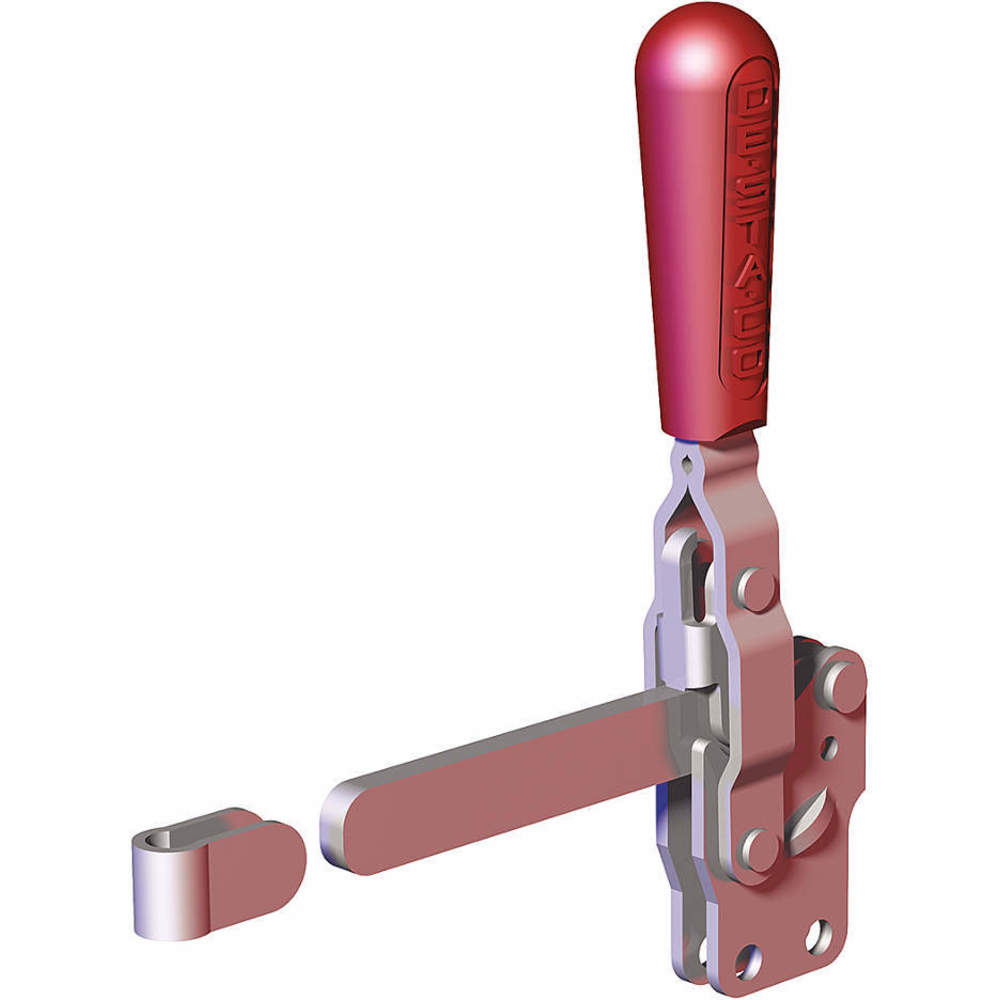

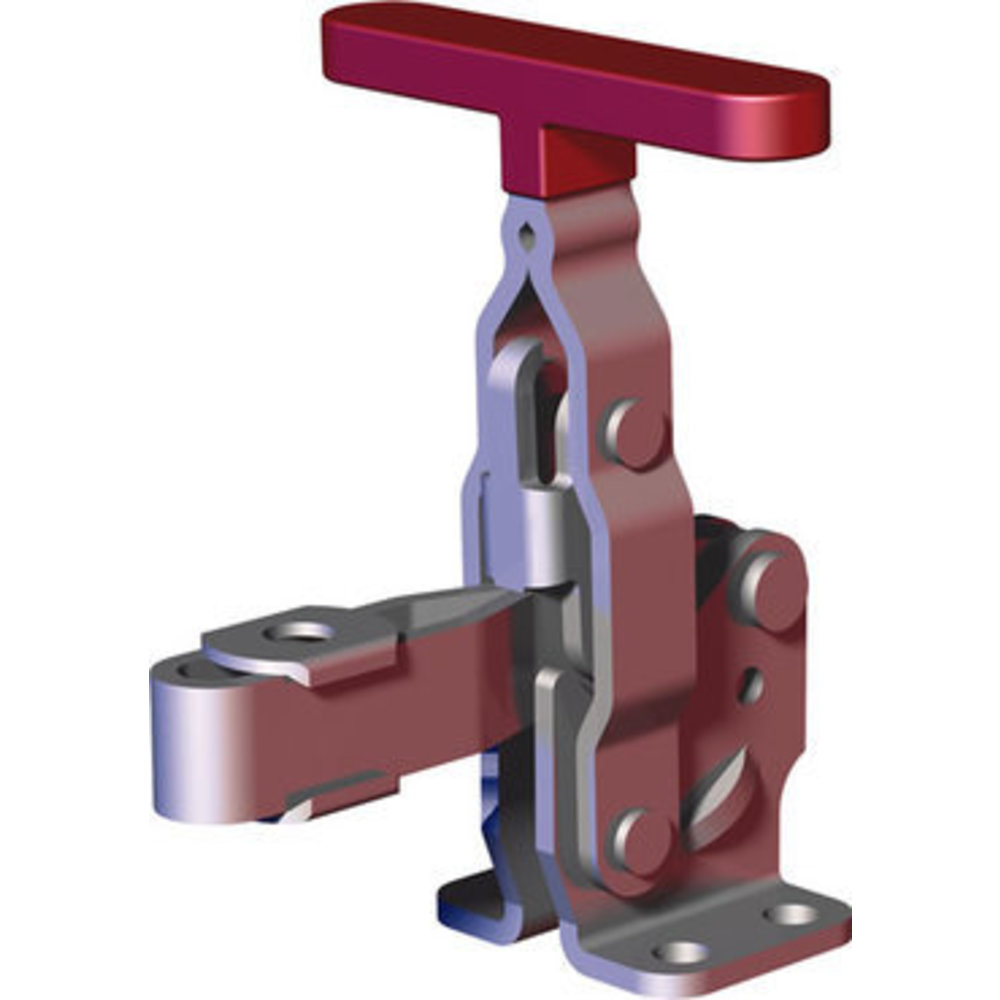

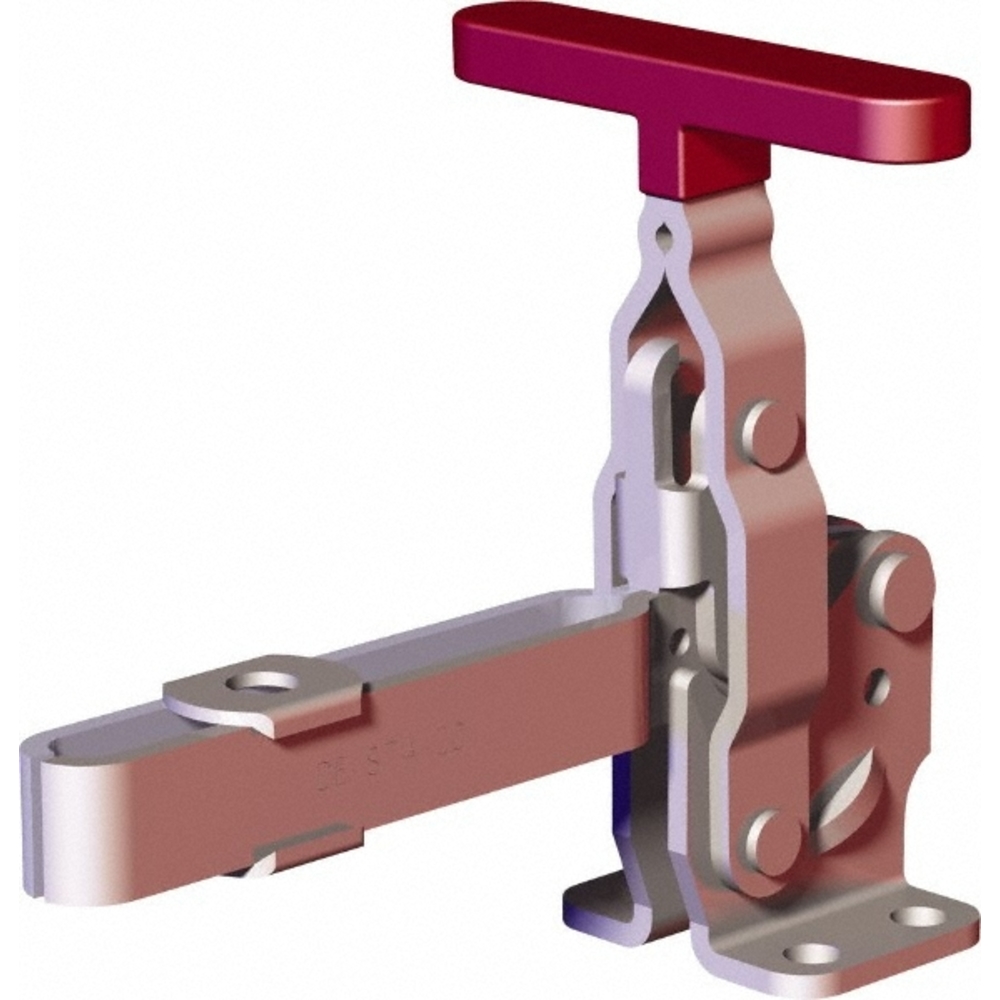

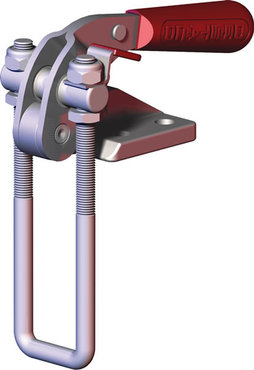

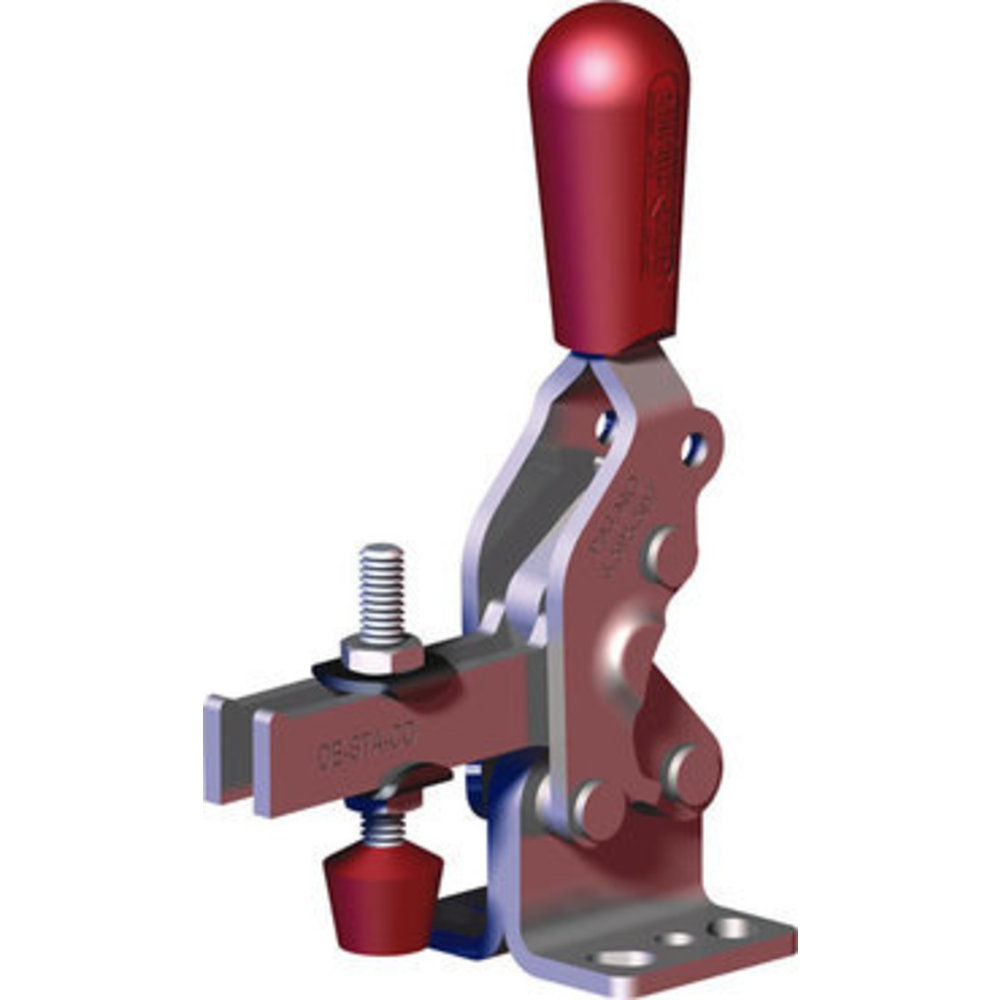

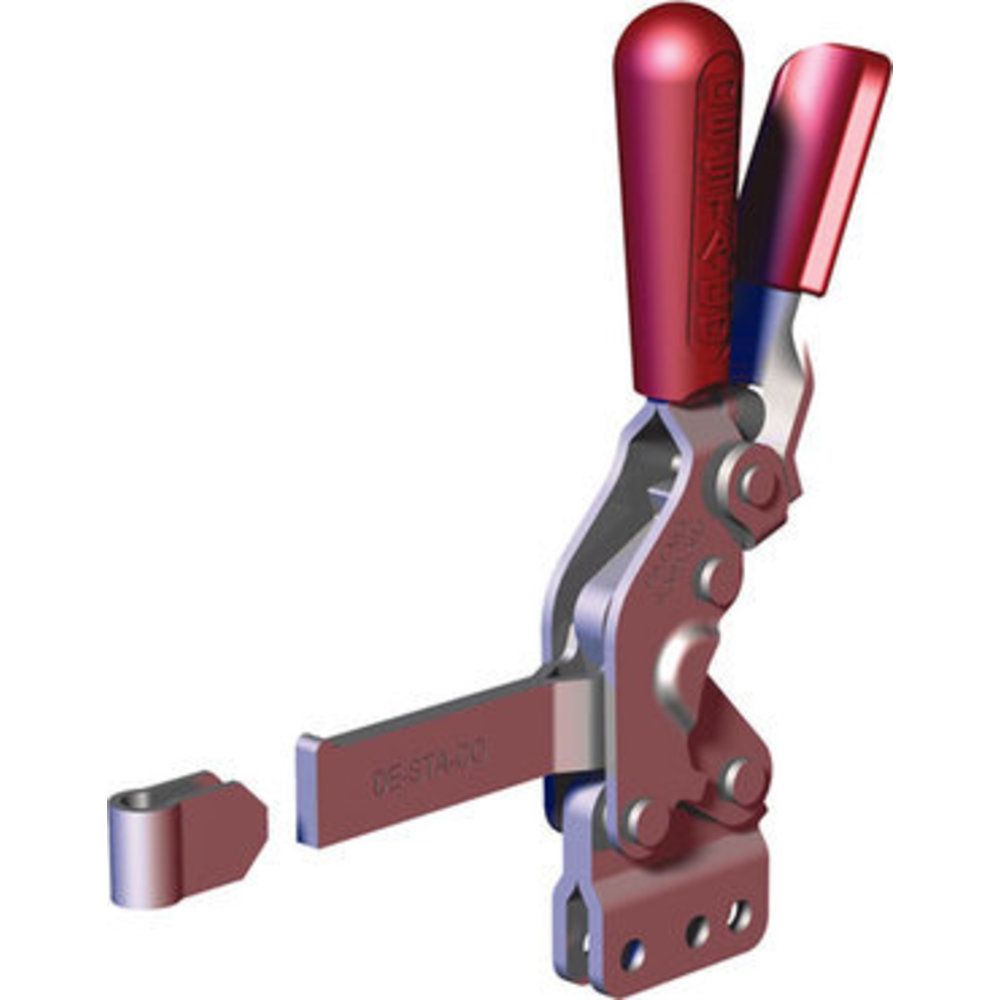

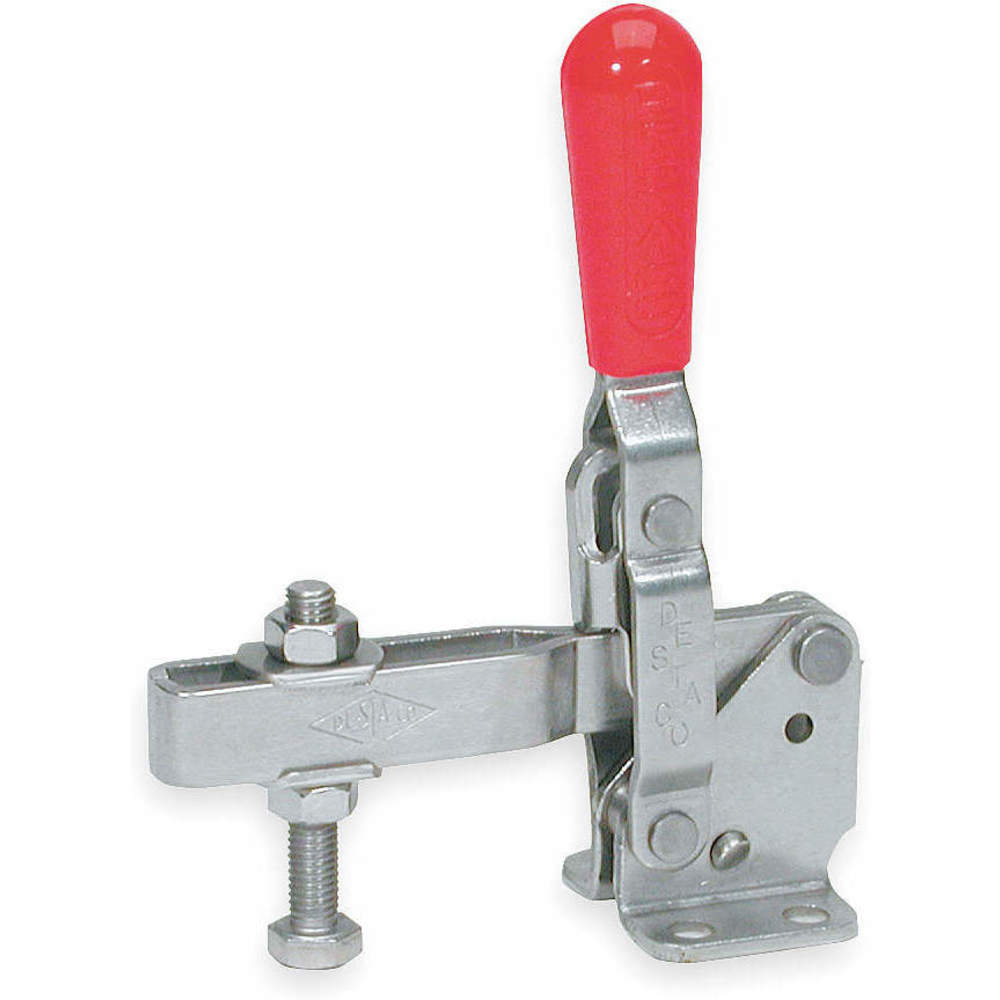

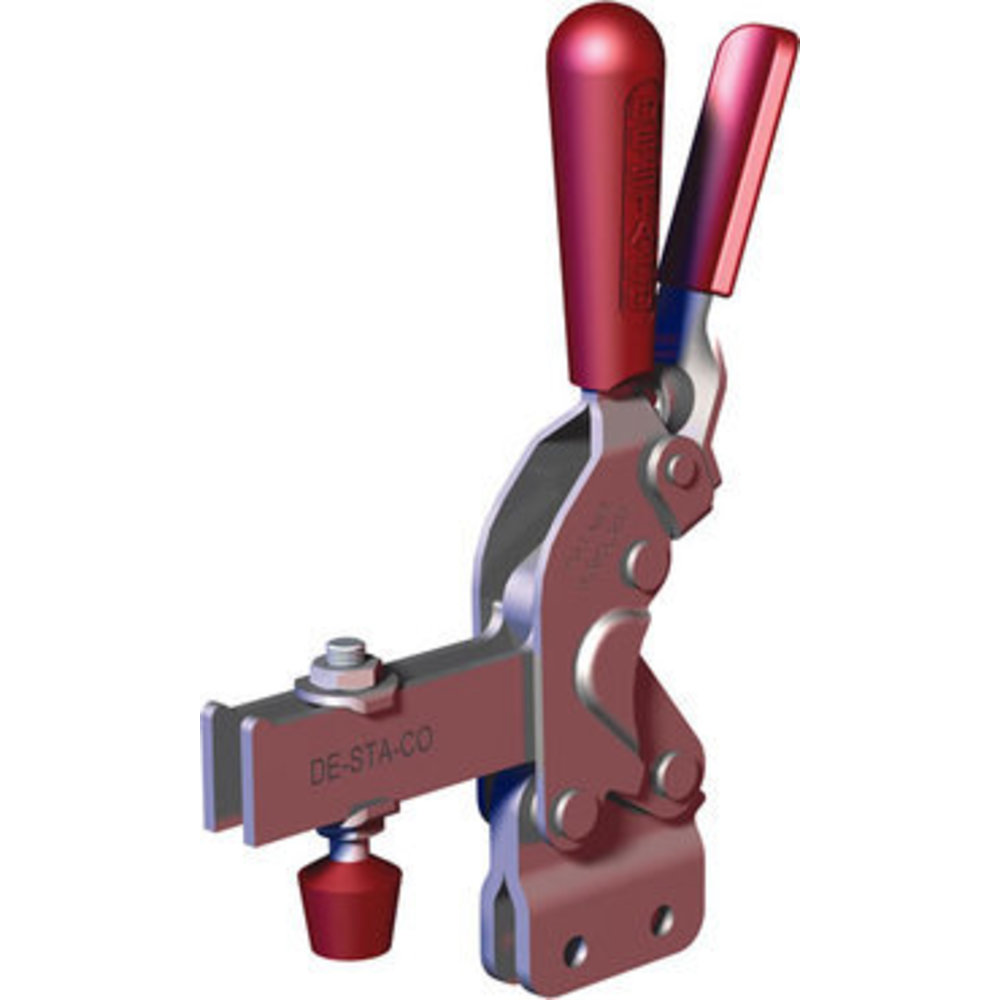

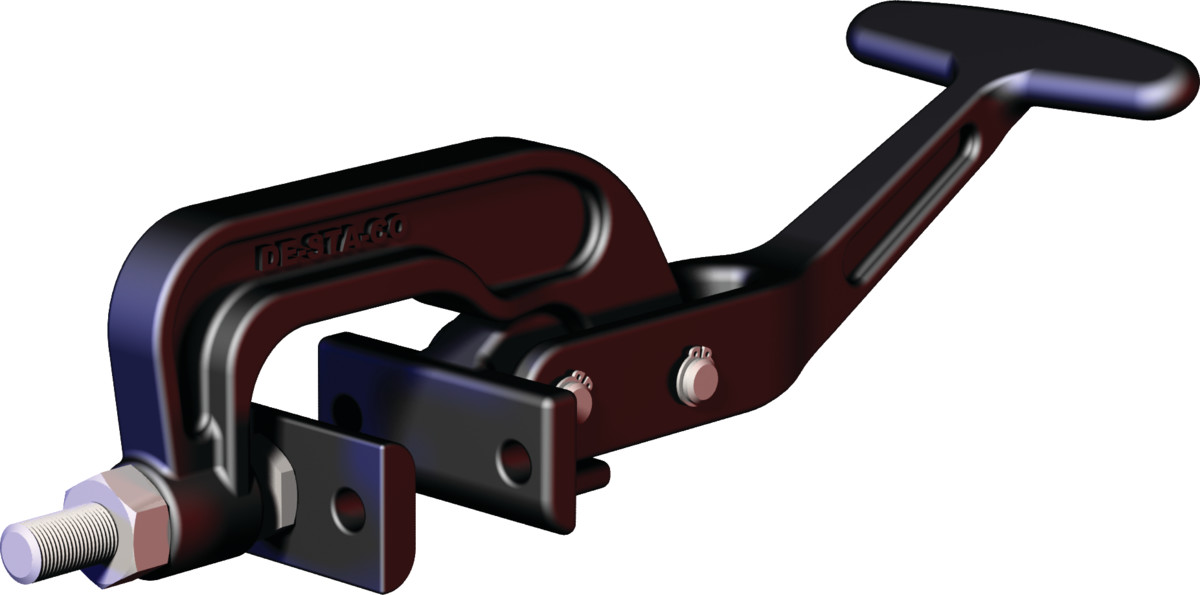

Destaco 2013 Series Clamps

:

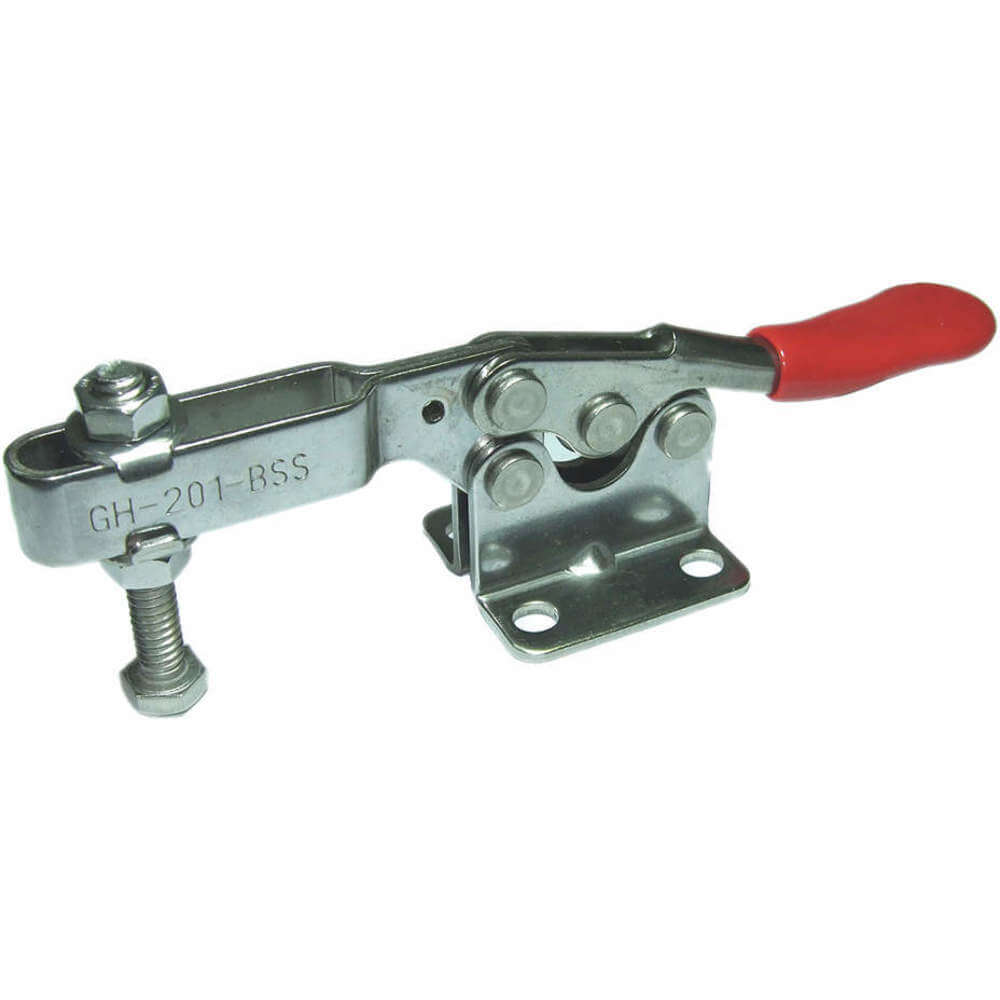

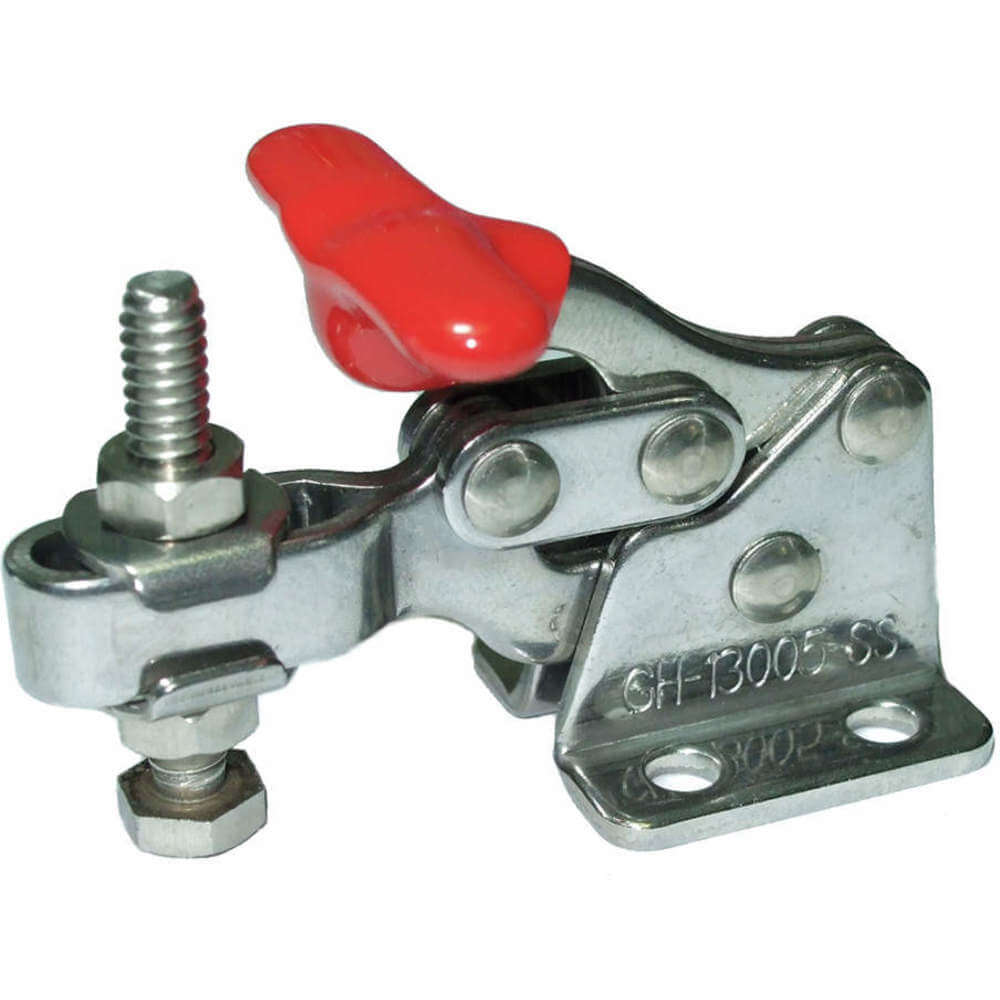

- They have increased handle clearance to reduce pinch points, as well as a fixed-handle pivot for smooth operation.

- These Destaco horizontal hold-down clamps are used in woodworking, fixture checking, light machining and equipment testing.

- They also have a U-shaped arm with a maximum carrying capacity of 295 lb (133.81 kg).

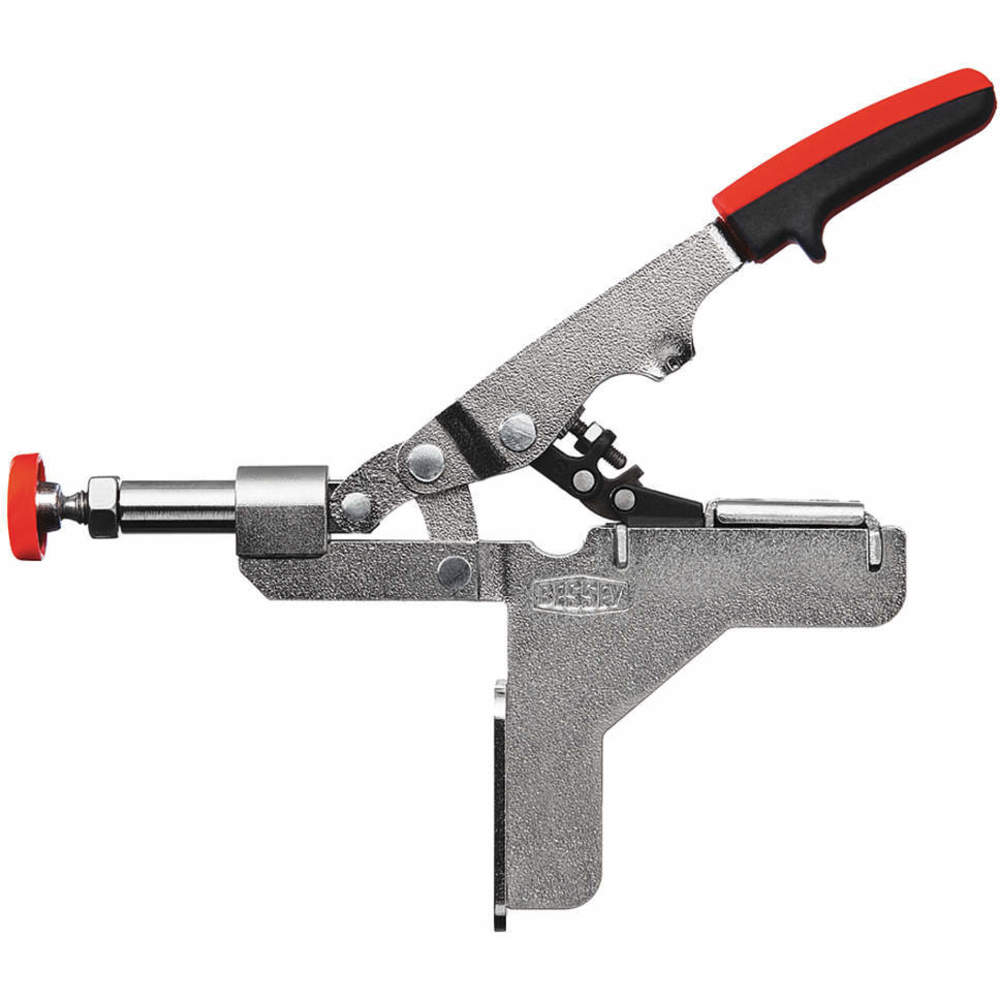

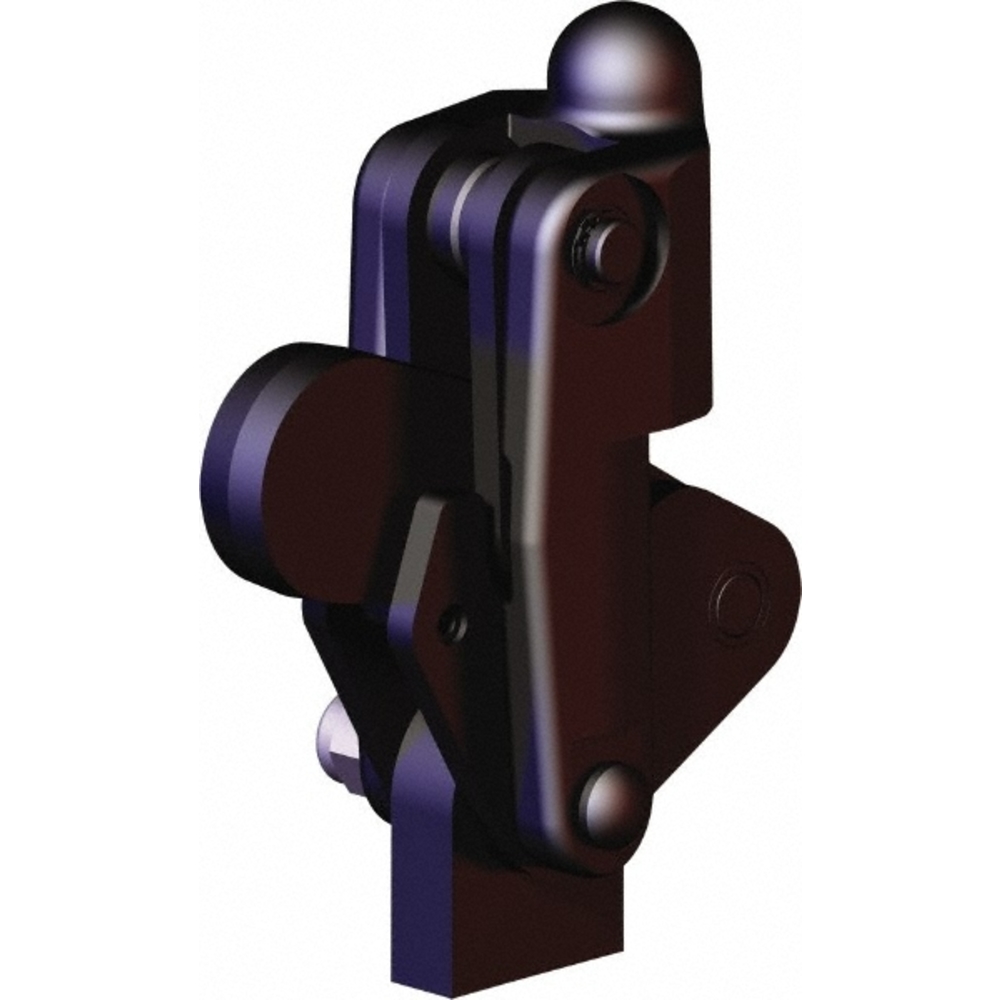

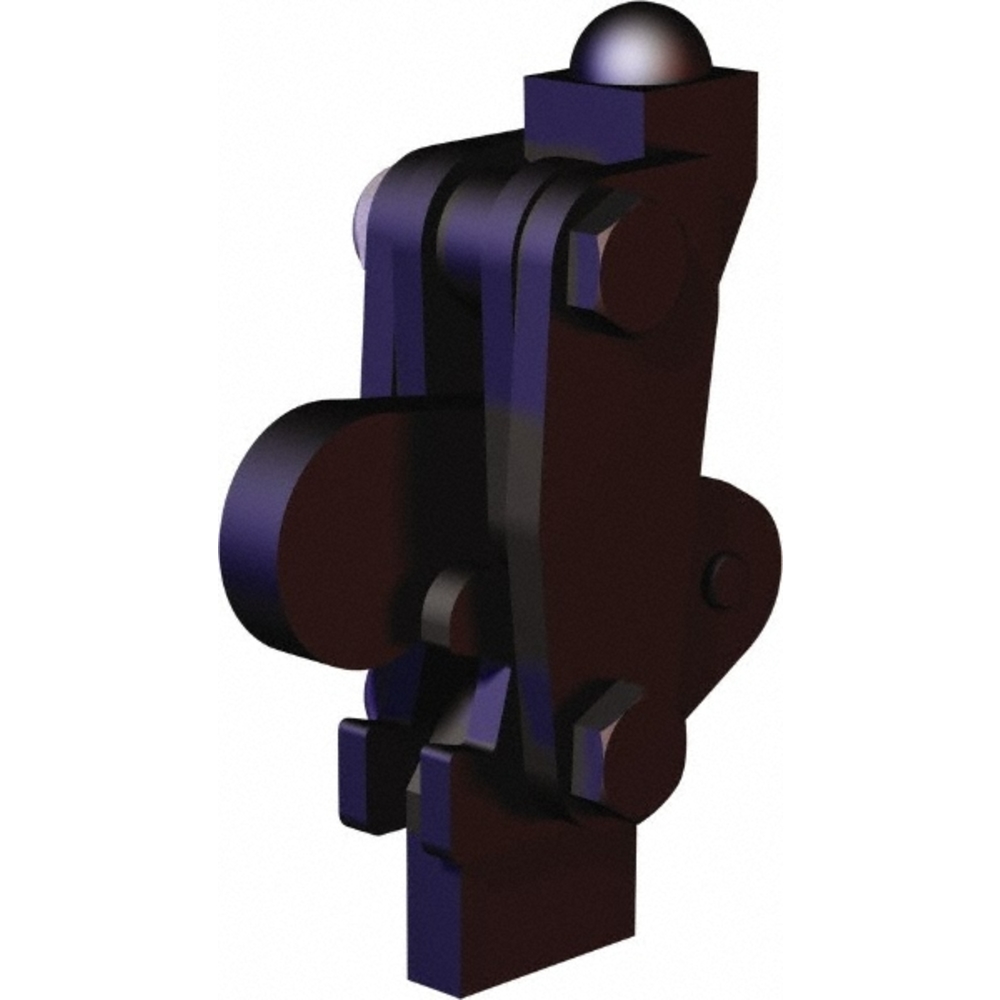

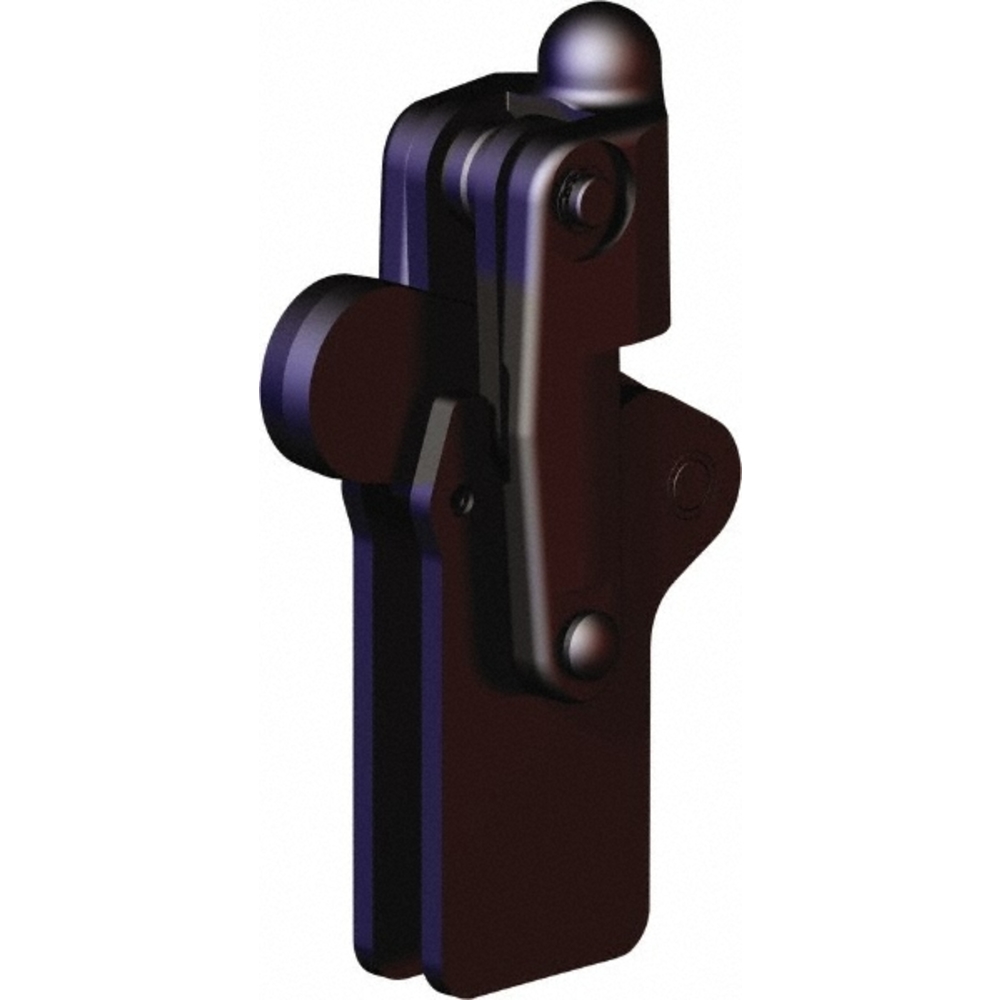

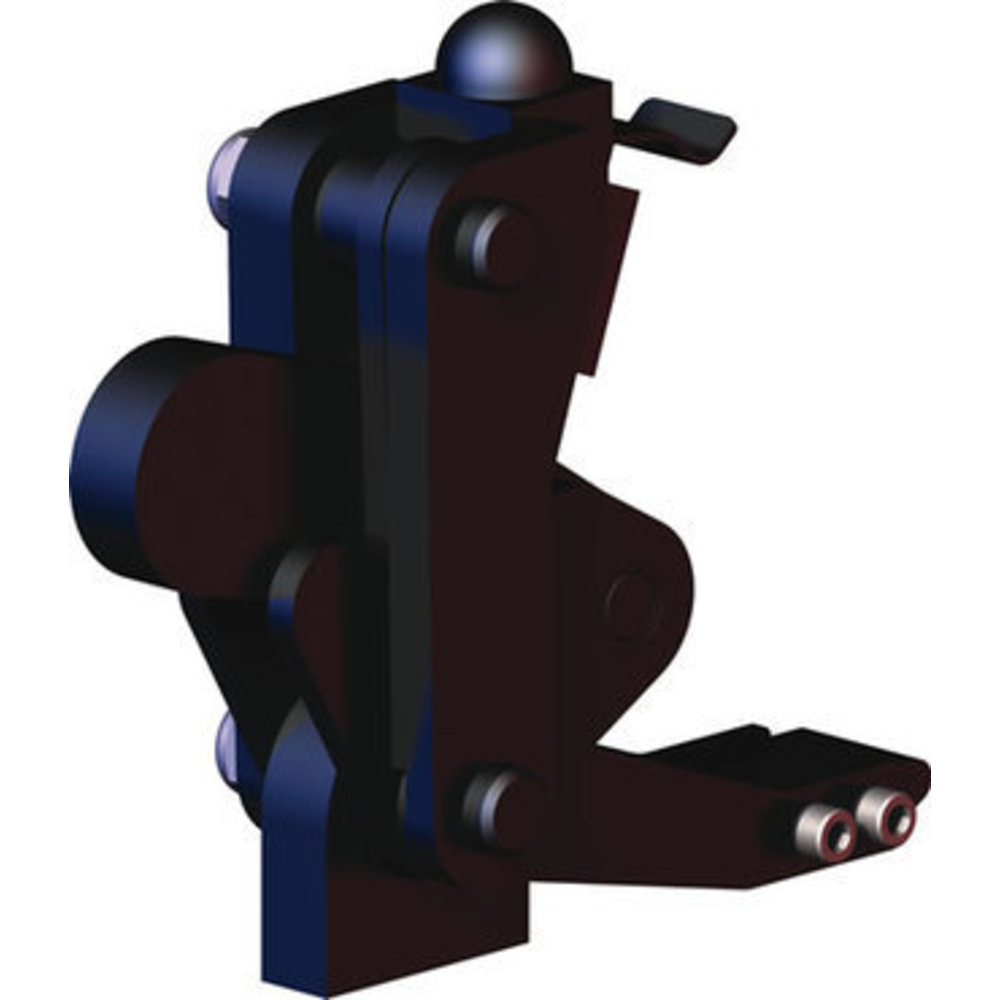

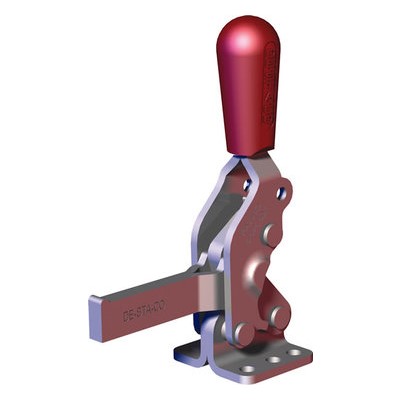

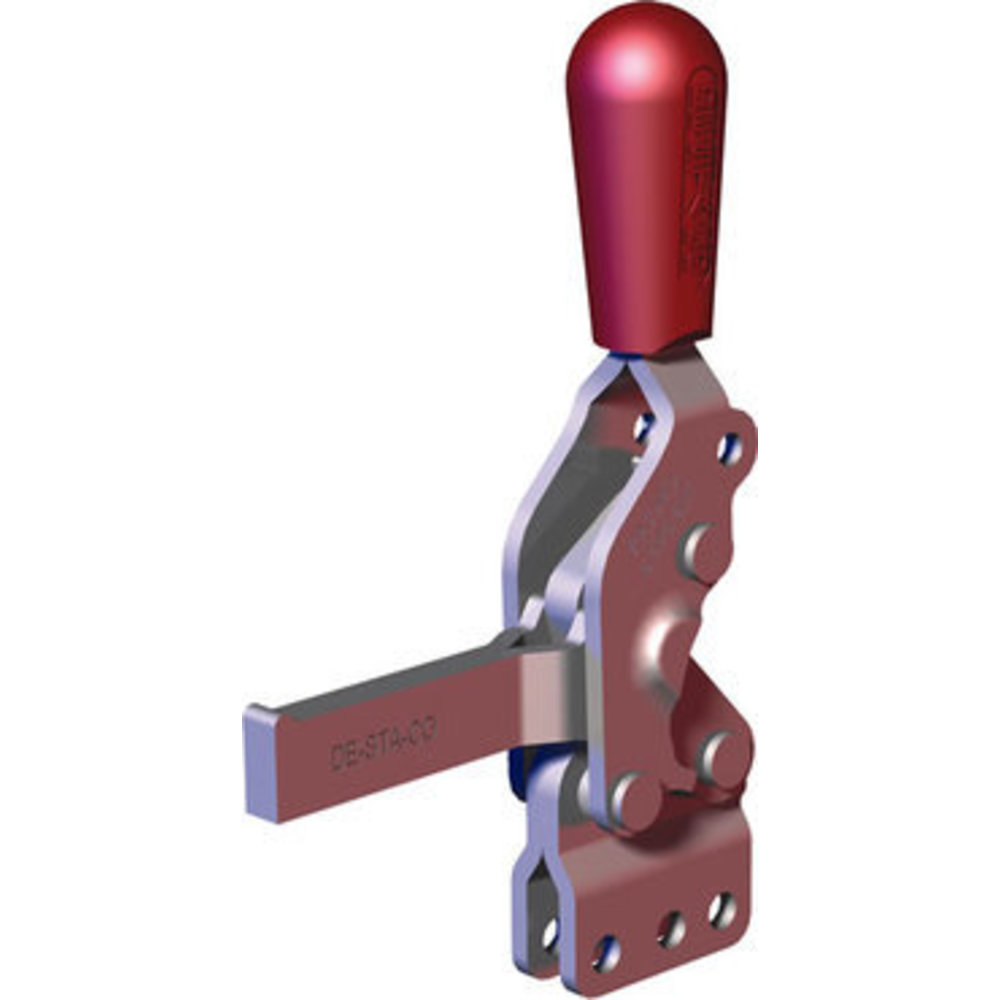

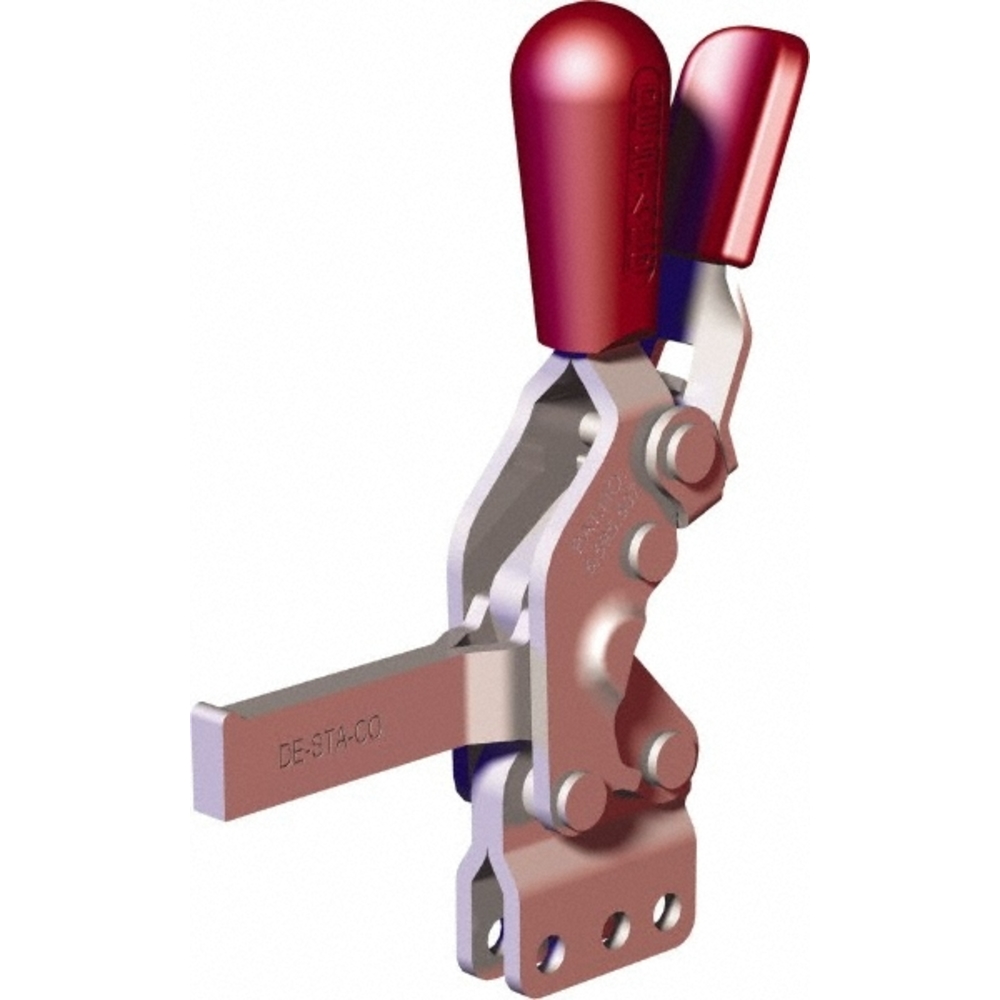

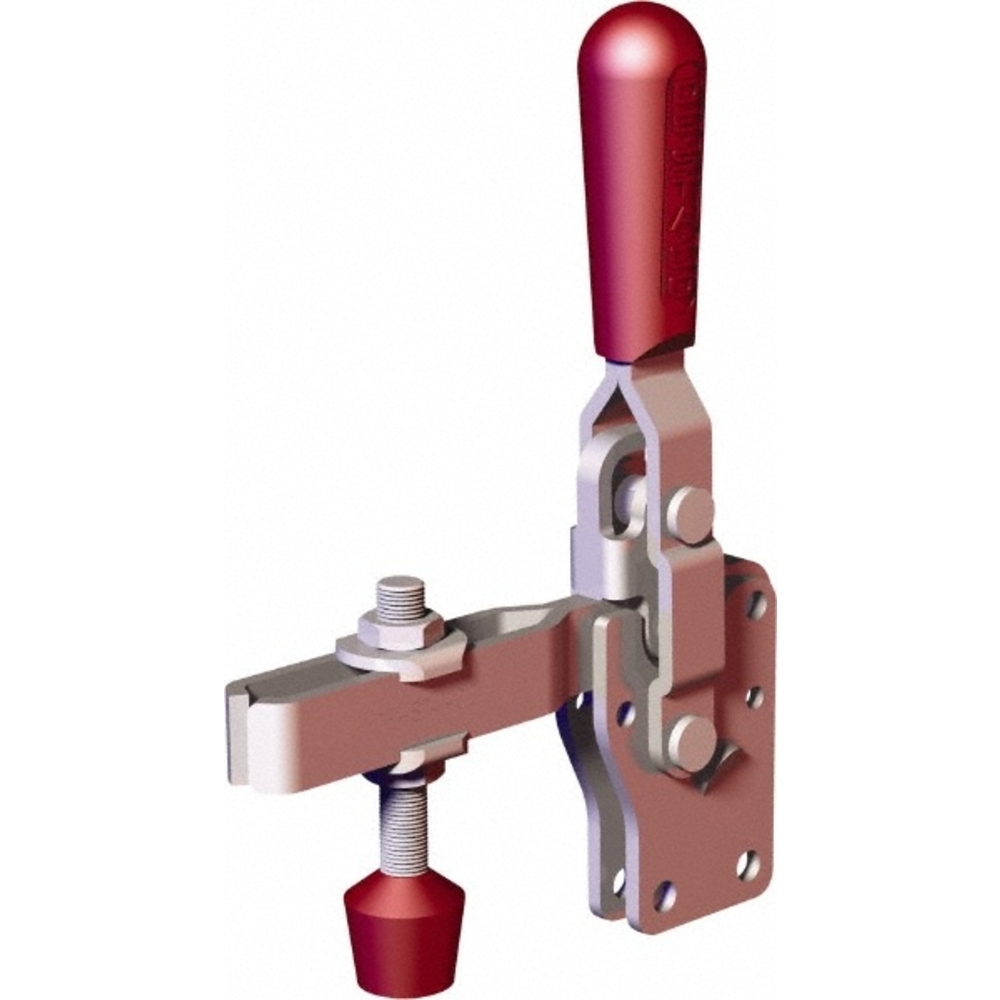

Bessey Auto-adjust Toggle Clamps

:

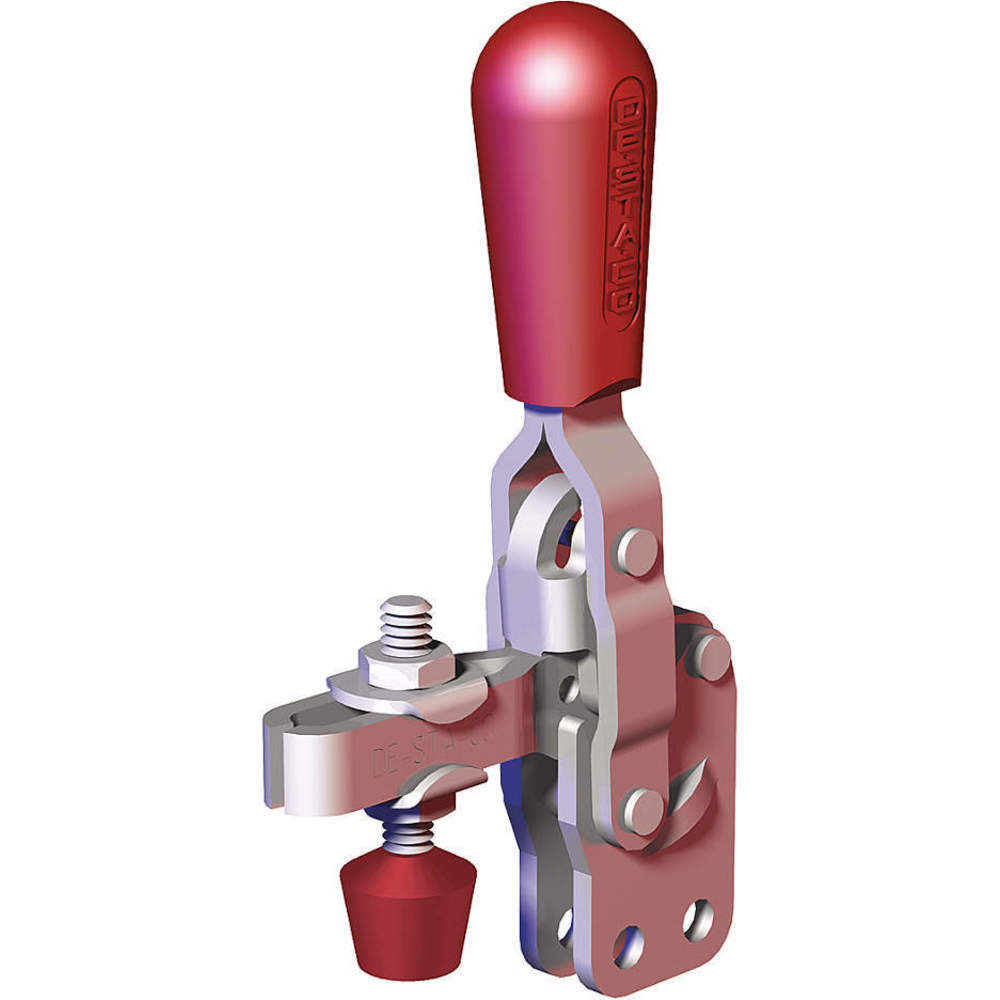

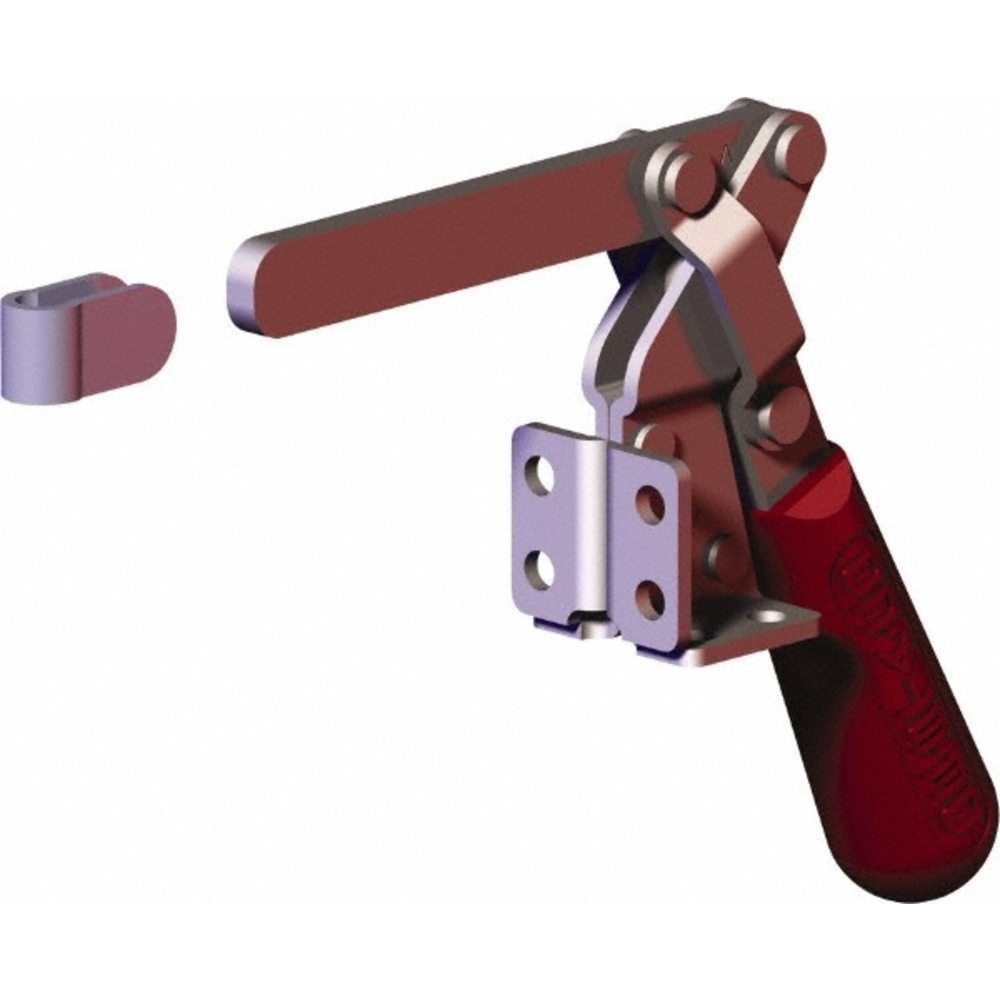

- They automatically adjust to changes in workpiece height while maintaining a constant clamping force.

- These Bessey vertical toggle clamps have large handles with soft insets for comfortable operations.

- They have an adaptable base plate with precisely spaced holes for easy mounting.

£ GBPChange Country

£ GBPChange Country