Uses

Pneumatic clamps offer a wide combination of features, making them useful for CNC machining, automotive part assembling and fixture checking in the aerospace, automotive and food processing & packaging industries.

Features

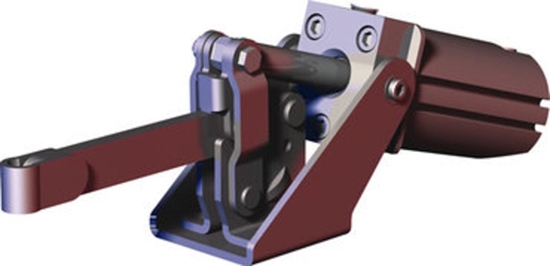

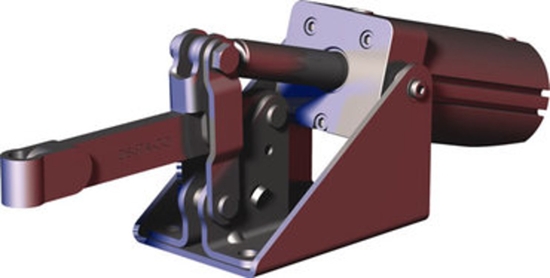

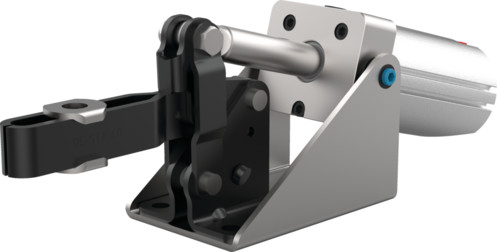

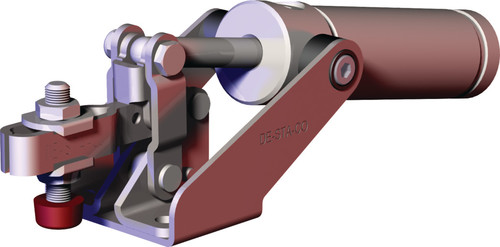

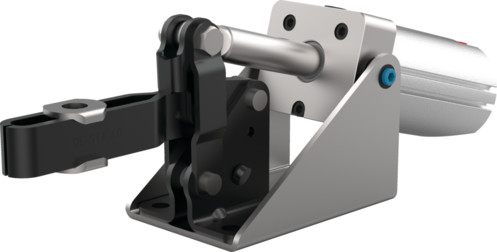

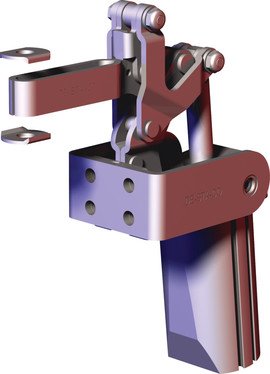

Destaco pneumatic toggle and fastening clamps:

- Destaco pneumatic clamps have aluminium / steel construction for structural rigidity and corrosion resistance.

- Selected models come equipped with hardened rivets & bushings at pivot points to fix, rotate & move the handle bar for the required work position.

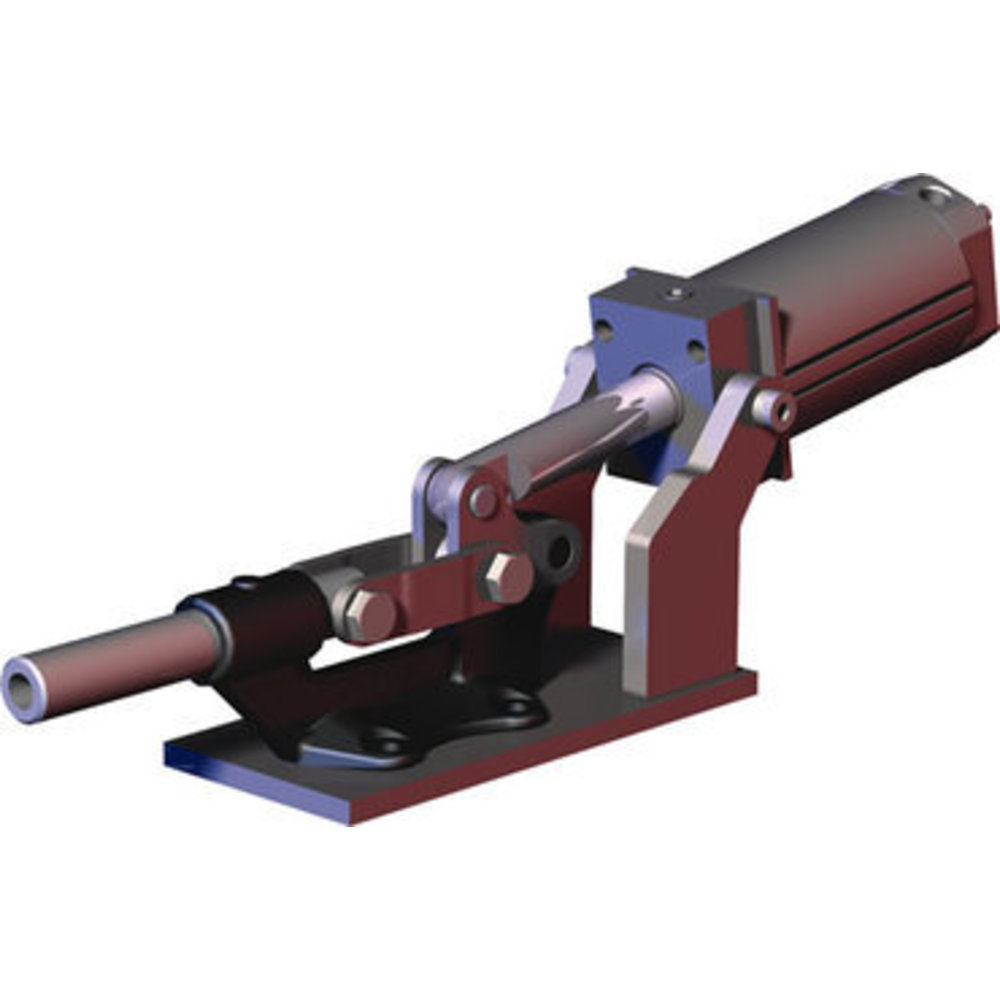

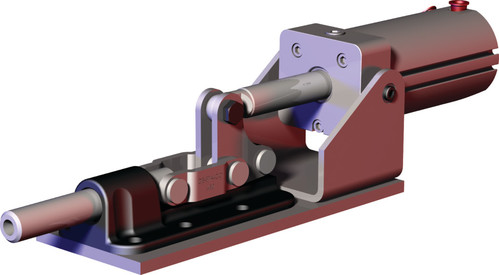

- The clamps contain a pneumatic cylinder with an input port for connecting to a source of compressed air.

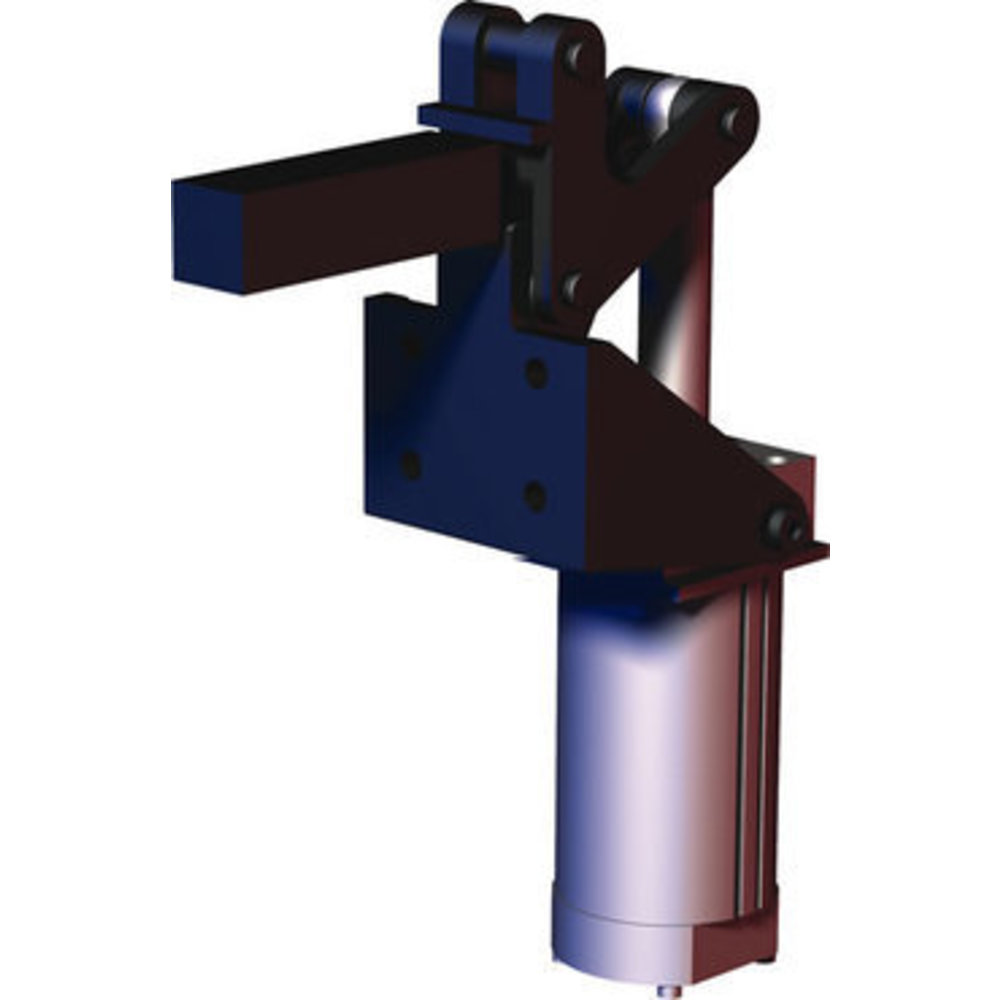

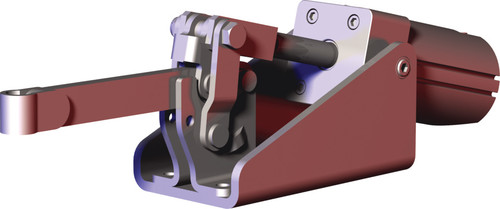

- Destaco pneumatic power clamps are equipped with a patented Toggle Lock mechanism for locking the clamp in a fixed position, if a sudden pressure drop or hose disconnection is detected. These clamps offer easy surface mounting, with the ability to mount from front, rear or sides of the clamp.

Guardair pneumatic clamps:

- Guardair lid clamps are designed to be used with 4, 8 and 15 gallon vacuums, and are available in packs of 3.

- The grounding clamps are 20 foot accessories of the brand's vacuums. They are suitable for grounding methods in applications with high static buildup.

Working Mechanism

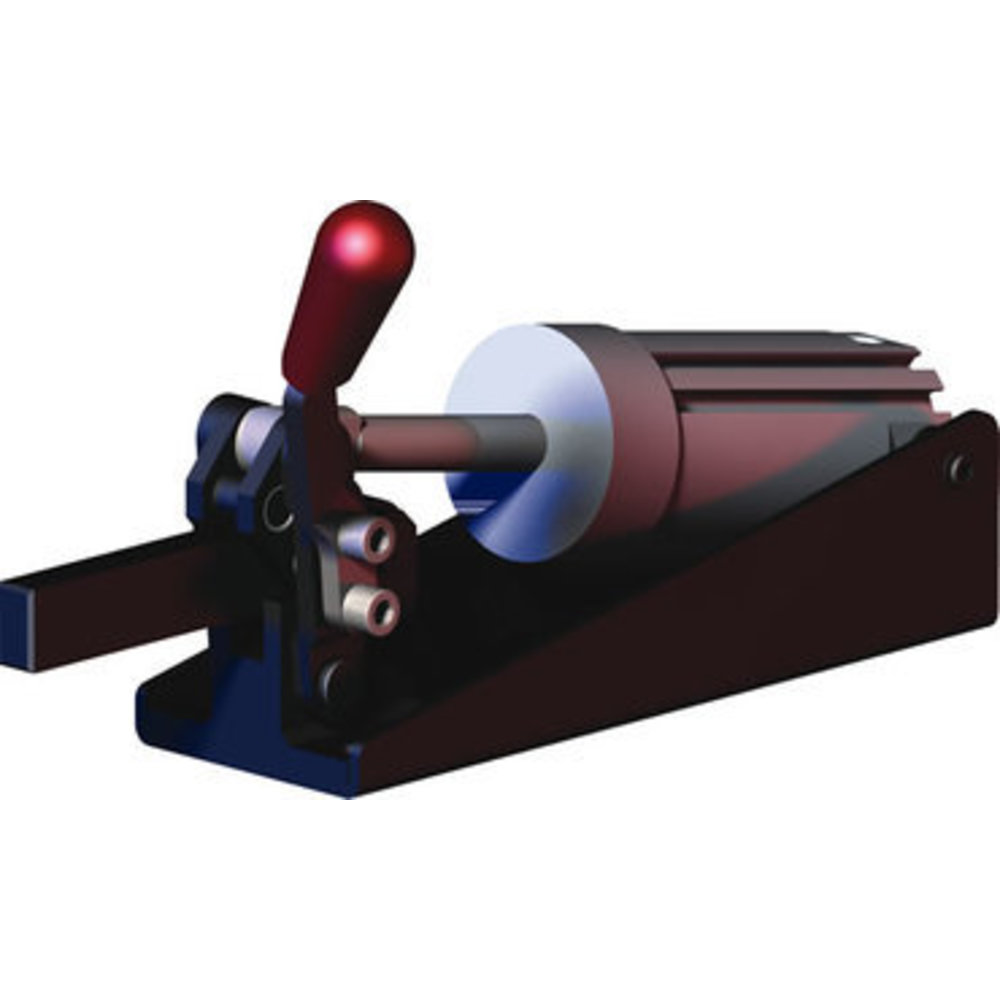

Destaco pneumatic clamp units are integrated with air actuated cylinders for applying clamping pressure & holding workpieces in place. The air pressure is applied in the clamping port, which moves the clamping arm to hold the workpiece. The required clamping force is achieved and exerted on the workpiece for holding it firmly. For unlocking the clamp, the air pressure is applied in the unclamping port. They are completely self contained & require only a pressure source for safety.

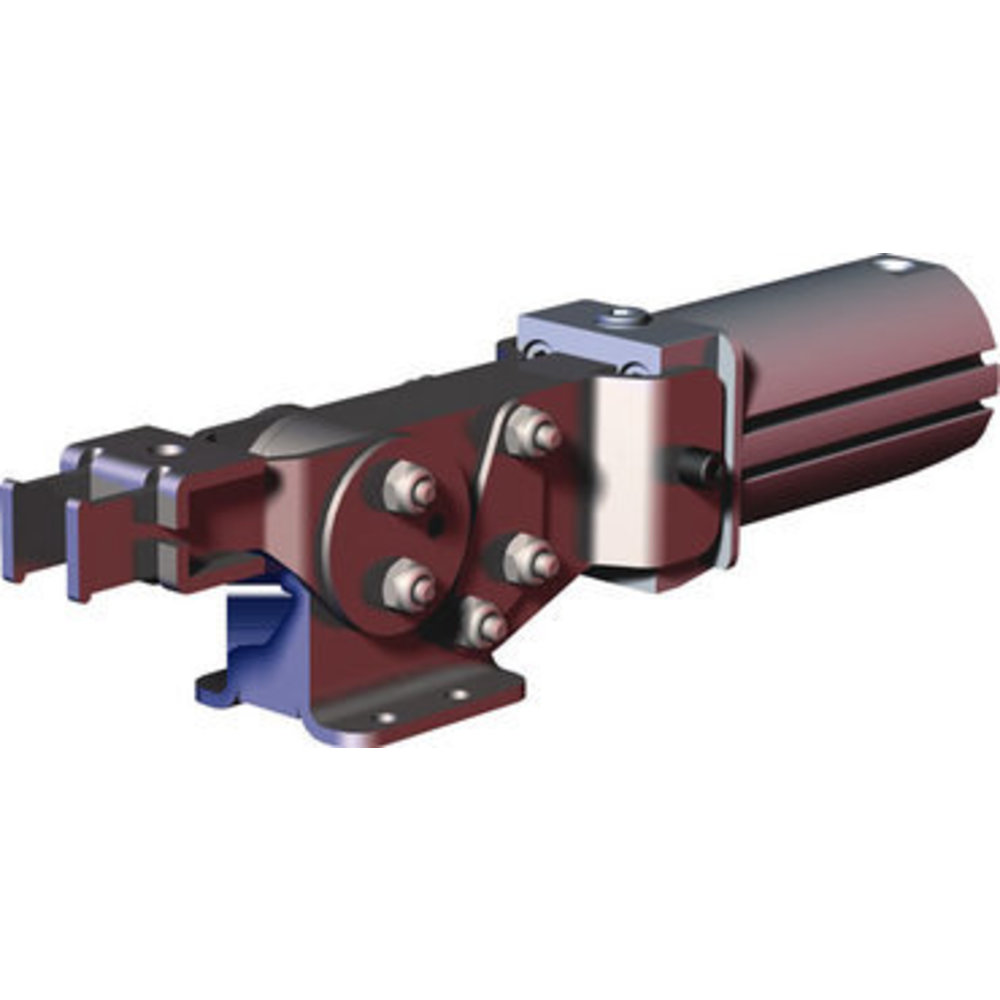

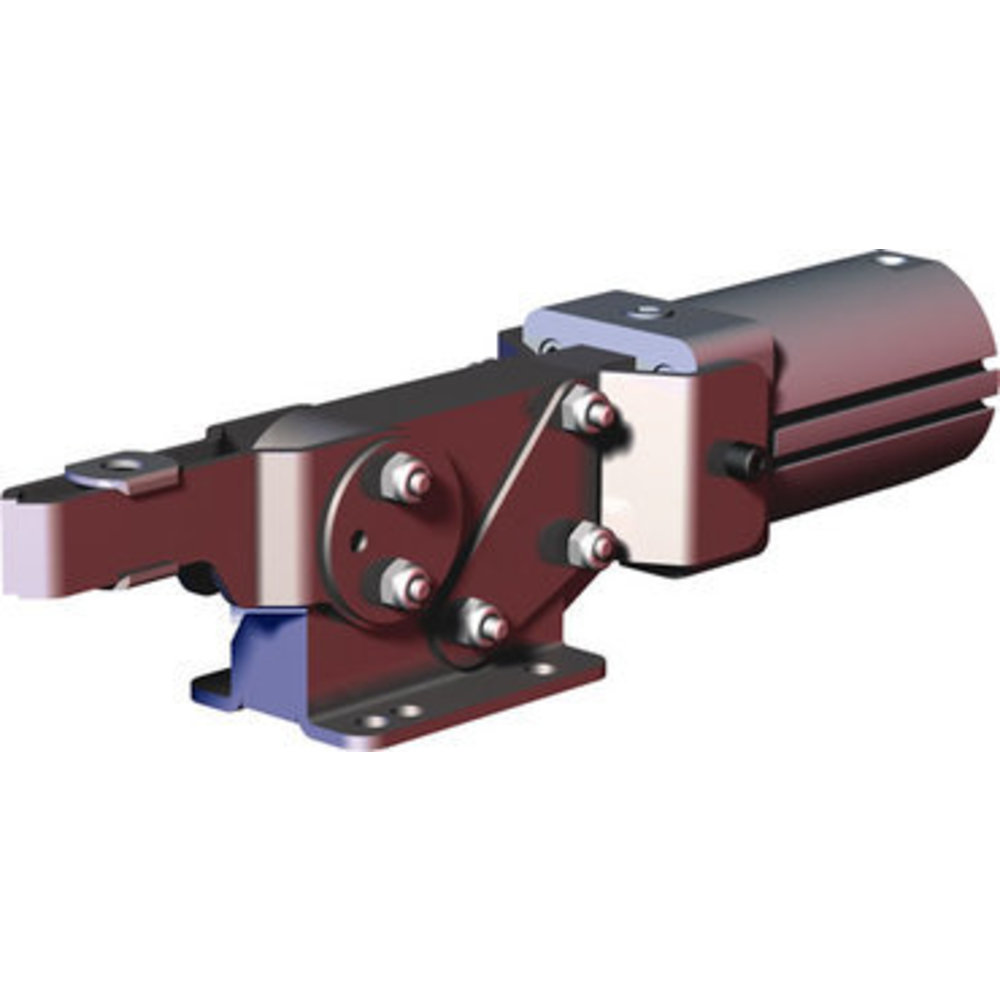

Destaco pneumatic swing clamps employ a strong hydraulic clamp mechanism that is intended to provide quick swing-and-clamp movement in secondary manufacturing operations on both metallic and non-metallic products, to ensure improved productivity. They deliver clamping force in direct proportion to inlet pressures and bore sizes, as well as offer field adjustable swing direction (left / right). These units offer lock angle repeatability with high accuracy, thereby making clamping on an extremely compact area easily possible.

Destaco pneumatic power clamps are equipped with hardened rivets & bushings at pivot points to fix, rotate & move the handle bar for the required work position. They contain a pneumatic cylinder with an input port for connecting to a source of compressed air for powerful clamping.

Frequently Asked Questions

How do Guardair compressed air-powered vacuums work?

Pneumatic air-powered vacuums or compressed vacuums operate on the Venturi principle. Via the air supply hose, compressed air enters the Venturi box and travels through the injector. As the air continues through the surrounding Venturi, it accelerates, thereby creating low pressure inside the Venturi box. This low pressure induces vacuum flow inside the adjacent canister, and in turn, through the attached vacuum hose.

What is the Toggle Lock Plus mechanism?

Selected Destaco straight line action clamps feature the Toggle Lock Plus mechanism to prevent accidental opening of clamps.

What is the recommended operating air pressure for Guardair safety air guns?

Guardair in-plant air compressors are recommended for operation at pressures ranging from 80 to 120 psi.

Which grease is ideal for Destaco clamps for their rebuilding?

A coupling grease like Mobil XTC should be used when dealing with Destaco mechanical clamps, while the Magnalube G grease is great for use with pneumatic cylinder seals.

What does clamping force mean?

Clamping force is the amount of force actually applied to the workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

What does a clamp's holding capacity signify?

The clamp's holding capacity or holding force represents the capability to hold down mechanical equipment or sheet metal while assembling automotive parts or during manufacturing processes.

What is the significance of the red colour of the handle of Destaco clamps?

There is no such significance of the colour of the clamp's handle, as it only represents a recognisable area. This helps operators in finding the handle quickly & easily.

How are straight line action clamps installed?

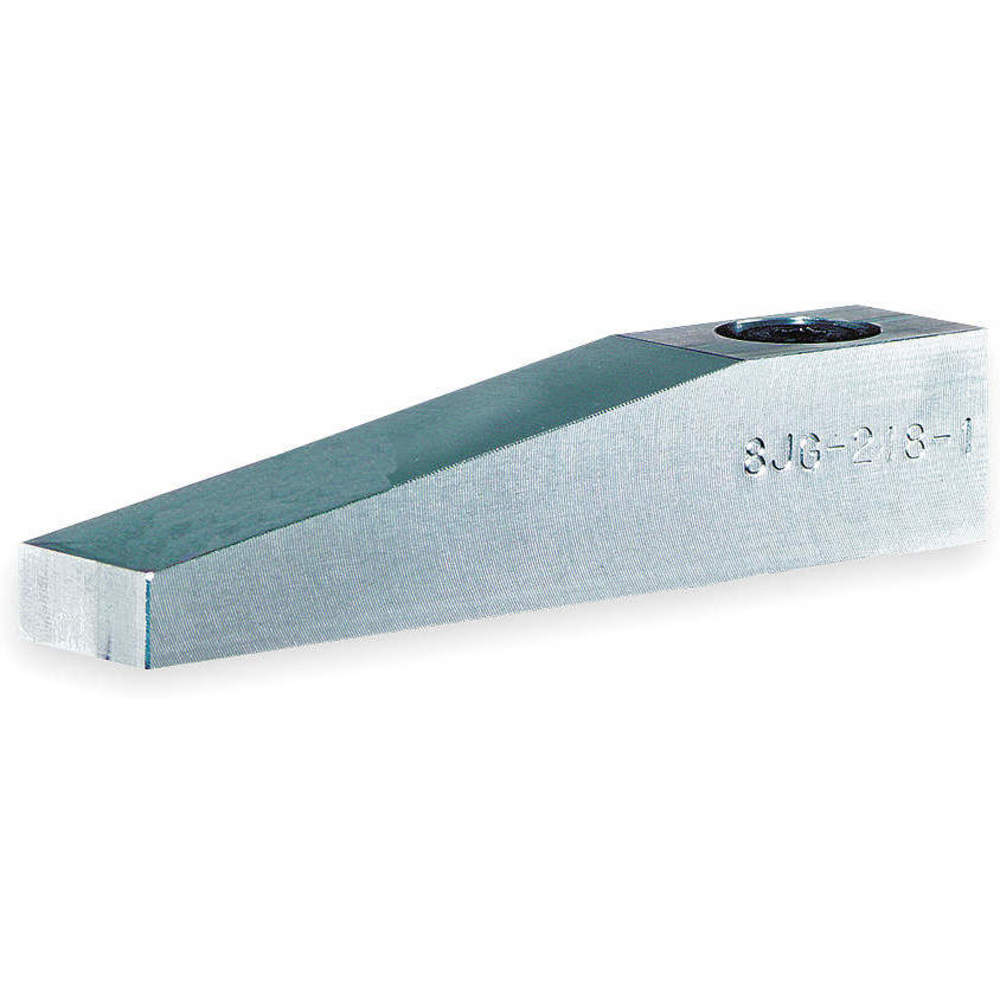

Destaco straight line action clamps come with through holes on the flanged or straight base that allow quick and secure surface or blade mounting onto flat surfaces / workpieces using simple screwing. They can be removed and installed at a different location by simply unscrewing using a screwdriver.

How are toggle clamps measured?

Toggle clamps are available in multiple variants having different holding capacities. The capacity of a particular toggle clamp can be measured by calculating the distance between the clamping plate (at its highest position) & the workbench.

Does Destaco supply any water resistant clamp sensors?

Yes, Destaco also supplies inductive sensors designed in accordance with IP65 standards to ensure protection from powerful hydraulic jets, dust & heavy rain.

£ GBPChange Country

£ GBPChange Country