Powergrip Kits

Include idler(s), belts, tensioner springs, tensioners, supporting hardware, detailed installation instructions and technical service bulletins.

V-Belts(9571 Products)

Tapered and QD Bushings(248 Products)

V-Belt Pulleys(111 Products)

Shrink Clamps(4 Products)

Round Belts(15 Products)

Synchronous Drive Gearbelts(10409 Products)

Universal Couplings(2527 Products)

Hydraulic Hose Adapters and Plugs(1214 Products)

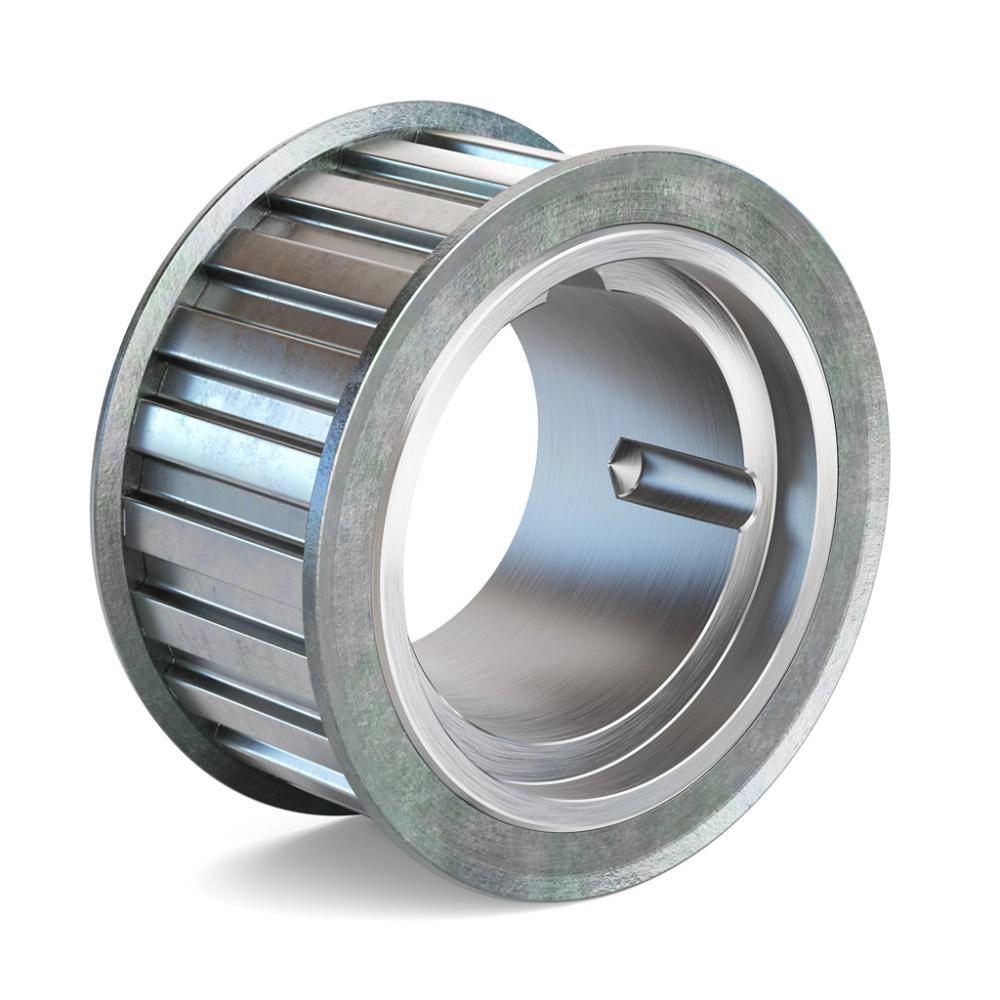

Synchronous Drive Gearbelt Pulleys(1196 Products)

Blocks and Sheaves(333 Products)

Hydraulic Bulk Hoses(264 Products)

Belts(210 Products)

Material Hoses(146 Products)

Air Hoses(83 Products)

Crimping Tool Dies(79 Products)

Sprockets(63 Products)

Hose Clamp Assortments(38 Products)

Cable and Wire Crimping Tools(25 Products)

Industrial and Fire Hose Nozzles(20 Products)

Gearbelt Idlers(19 Products)

Water Suction and Discharge Hoses(17 Products)

Spray Hoses(15 Products)

Conveyor Accessories(11 Products)

Tubing(11 Products)

Food Hoses(7 Products)

Flexible Gas Hoses(4 Products)

Hydraulic Hose Fittings(4 Products)

Hose Reel Accessories(3 Products)

Belt Accessories(2 Products)

Pressure Washer Accessories(2 Products)

Rubber Hose Accessories(1 Product)

Gates Corporation's MPNs cross individual references to the equivalent Dixon model numbers. So, if you are looking for competitor items that are either out of stock or obsolete, chances are Raptor Supplies has the equivalent Gates drive belts & pulleys available. Customers can also cross-reference most products using the last 5 digits of the model numbers.

Gates V-belts are available in thicknesses ranging from 8 mm to 18 mm. These belts, pulleys & bushings require careful packaging as some products might get damaged while shipping. Hence, these power transmission products are delivered by courier shipment and not air freight for minimum downtime.

Gates' extensive catalogue includes V-belts, tube fittings & adapters, power transmission kits, Gates hoses & couplings, water pumps and cooling fan modules. Gates SPB 4 rib metric V-belts are used to transfer force from the engine to hydraulic pumps, power steering systems and air conditioning compressors. They are heat & corrosion-resistant and require no lubrication / re-tensioning. These V-belts have elastomeric compounds with flex-bonded tensile cords for decreased distortion and stretching. These Gates belts feature wrapped construction for increased flexibility, improved grip and enhanced durability. They can withstand temperatures ranging from -30 to 140 degrees F. The brand's 1008 Series bushings come with a split in the barrel of the bushing for ease of installation and removal of the bushing. These bushings feature a taper lock style for secure locking, increased torque transmission and reduced vibration. They have a circle diameter of 1.328 inches and comply with SAE grade 5, ensuring moderate strength and reliability.

Include idler(s), belts, tensioner springs, tensioners, supporting hardware, detailed installation instructions and technical service bulletins.

Designed for construction and automotive applications where vibration, noise and premature failures can happen. Can easily fit on any vehicle for smooth running. Ideal for outdoor power equipment, appliances, machine tools, roller conveyors and exercise & medical equipment. Are oil, water and heat r...

Minimise component cost, maintenance and weight. Can withstand chemicals and rust. Assist in energy savings when replaced with older synchronous belts or V-belts.

Made of abrasion-resistant polyurethane with aramid or steel constructed cords for additional strength. Can be customised by adding profiles / coating or by special machining.

They are universally applicable and stronger, lighter & more flexible than conventional hydraulics hoses. They feature dense wire-braid reinforcement with XtraTuff Plus cover and provide enhanced abrasion & ozone resistance.

Gates Corporation is based in Denver, Colorado and manufactures fluid power products & power transmission belts.

It is recommended to change belts every 72 months.

Gates timing belts are made of HNBR elastomeric composites and feature a specially engineered tooth jacket & tensile cord for additional strength and heat resistance.

Gates shrink clamps differ from other brands' shrink clamps through their innovative design and engineering. With superior materials and advanced manufacturing techniques, Gates shrink clamps provide enhanced sealing, durability and reliability, making them a trusted choice for various applications where secure and long-lasting connections are required.