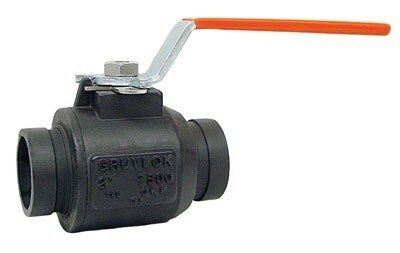

CTS SlideLOK

These ready-to-install couplings are designed to shorten installation time. The slide action ensures trouble-free installation. For added security, the patented gasket has four separate sealing surfaces. The predictive gap is a simple and quick indicator of proper assembly.