Uses

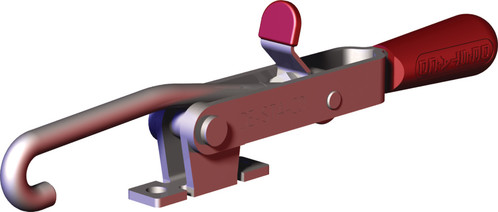

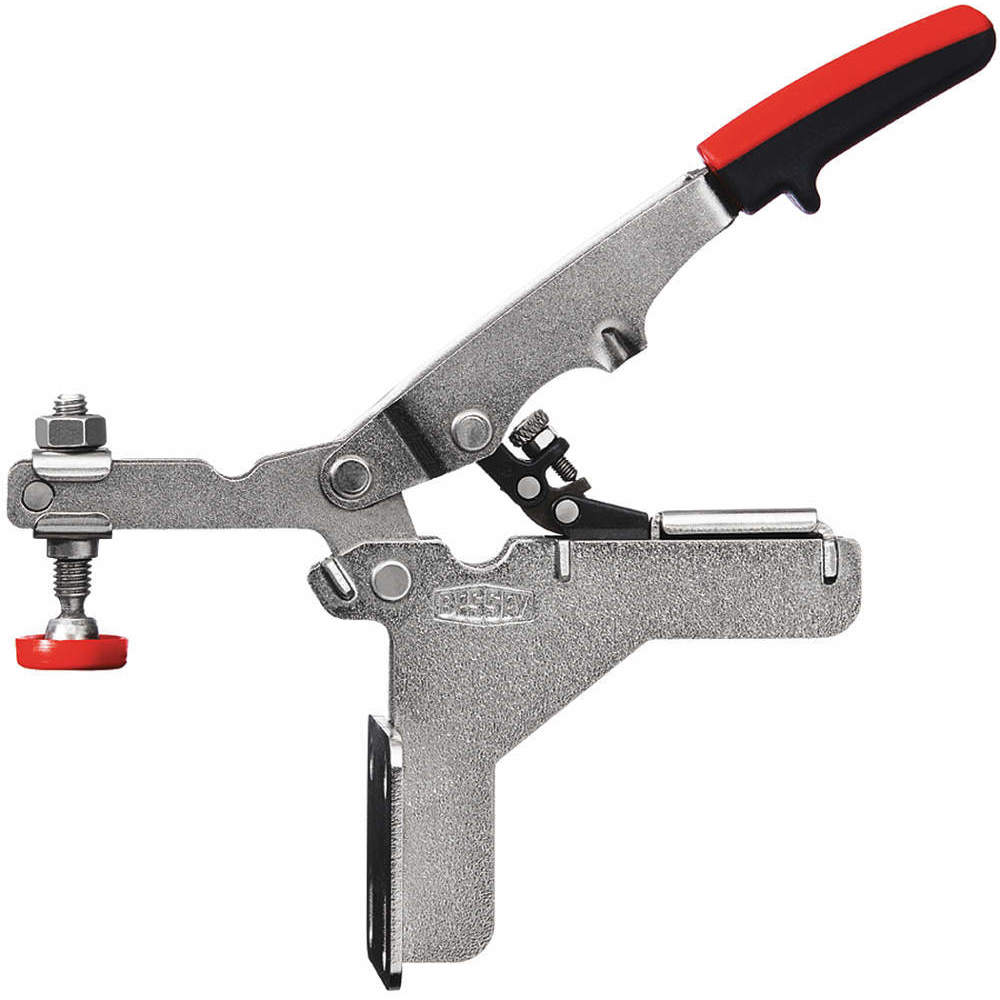

Horizontal toggle clamps incorporate a wide combination of features, making them useful for CNC machining, automotive part assembling and fixture checking in the aerospace, automotive and food processing & packaging industries.

Frequently Asked Questions

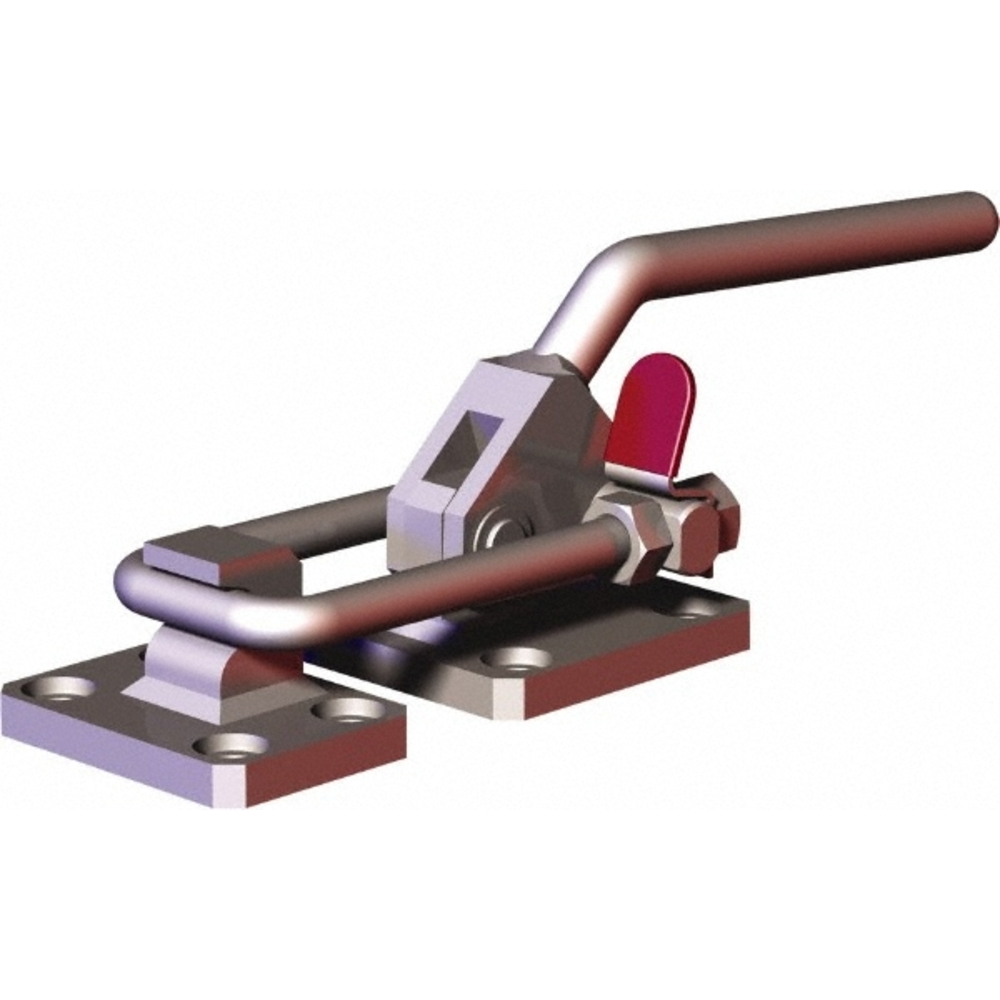

How are straight line action clamps installed?

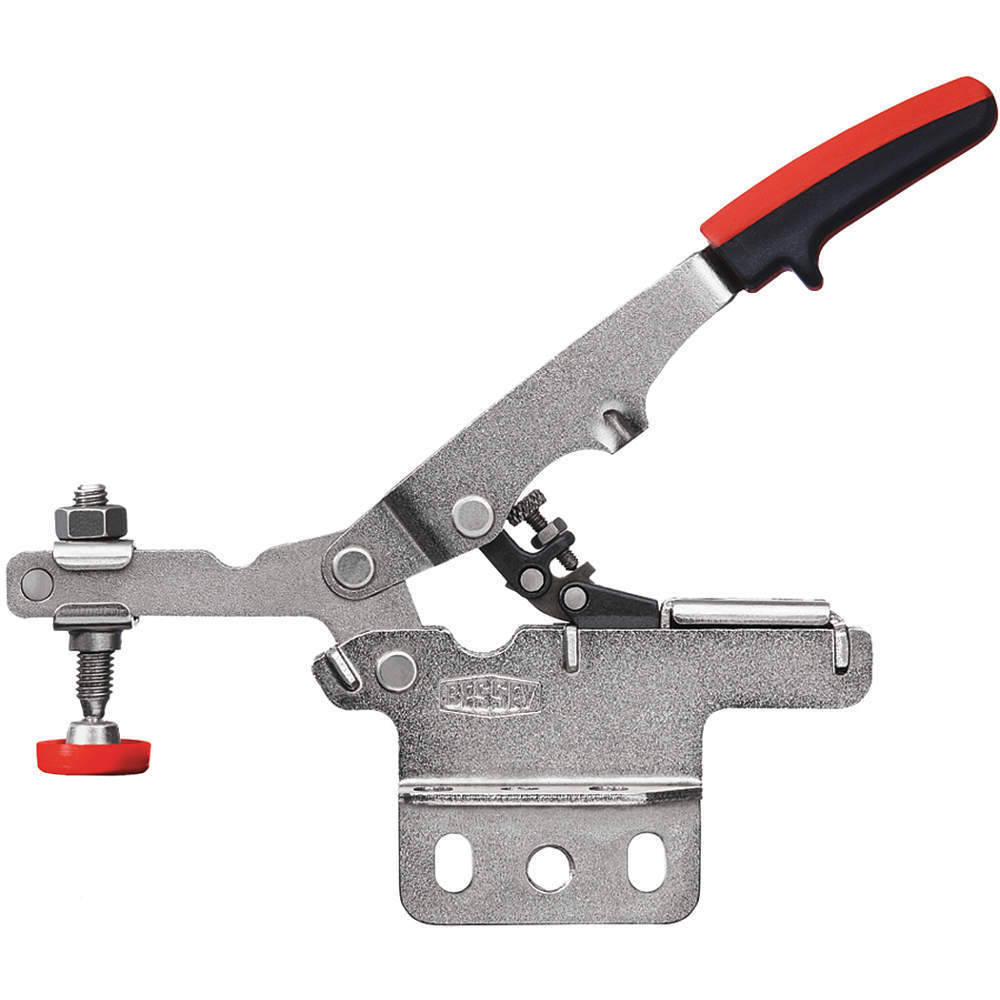

Destaco straight line action clamps come with through holes on the flanged / straight base that allow quick and secure surface or blade mounting onto flat surfaces / workpieces using simple screwing. They can be removed and installed at a different location by simply unscrewing using a screwdriver.

How are toggle clamps measured?

Toggle clamps are available in multiple variants having different holding capacities. The capacity of a particular toggle clamp can be measured by calculating the distance between the clamping plate (at its highest position) & the workbench.

Does Destaco supply any water resistant clamp sensors?

Yes, Destaco also supplies inductive sensors designed in accordance with IP65 standards to ensure protection from powerful hydraulic jets, dust & heavy rain.

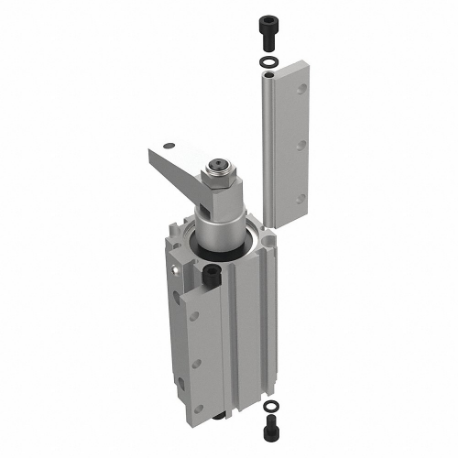

What does clamping force mean?

Clamping force is the amount of force actually applied to the workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

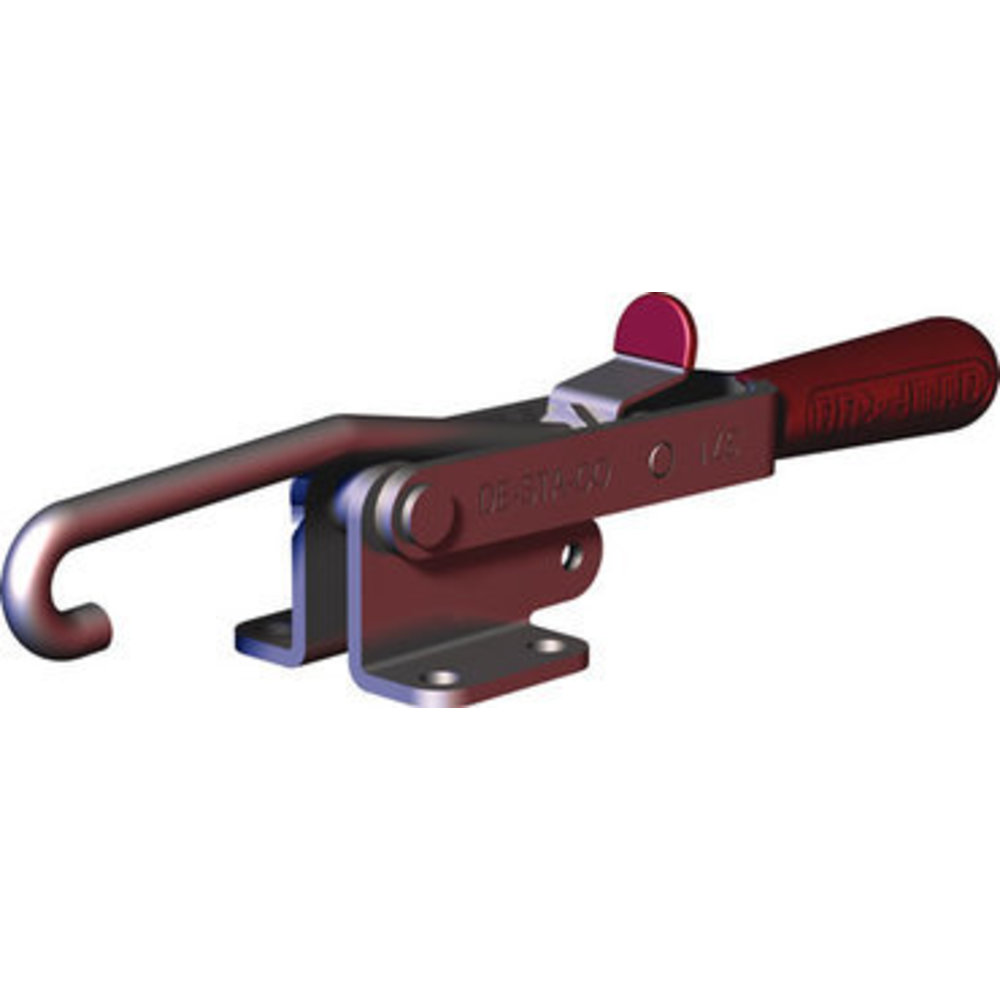

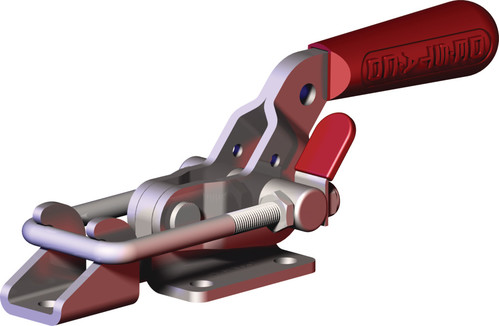

What is the difference between a vertical & horizontal toggle clamp?

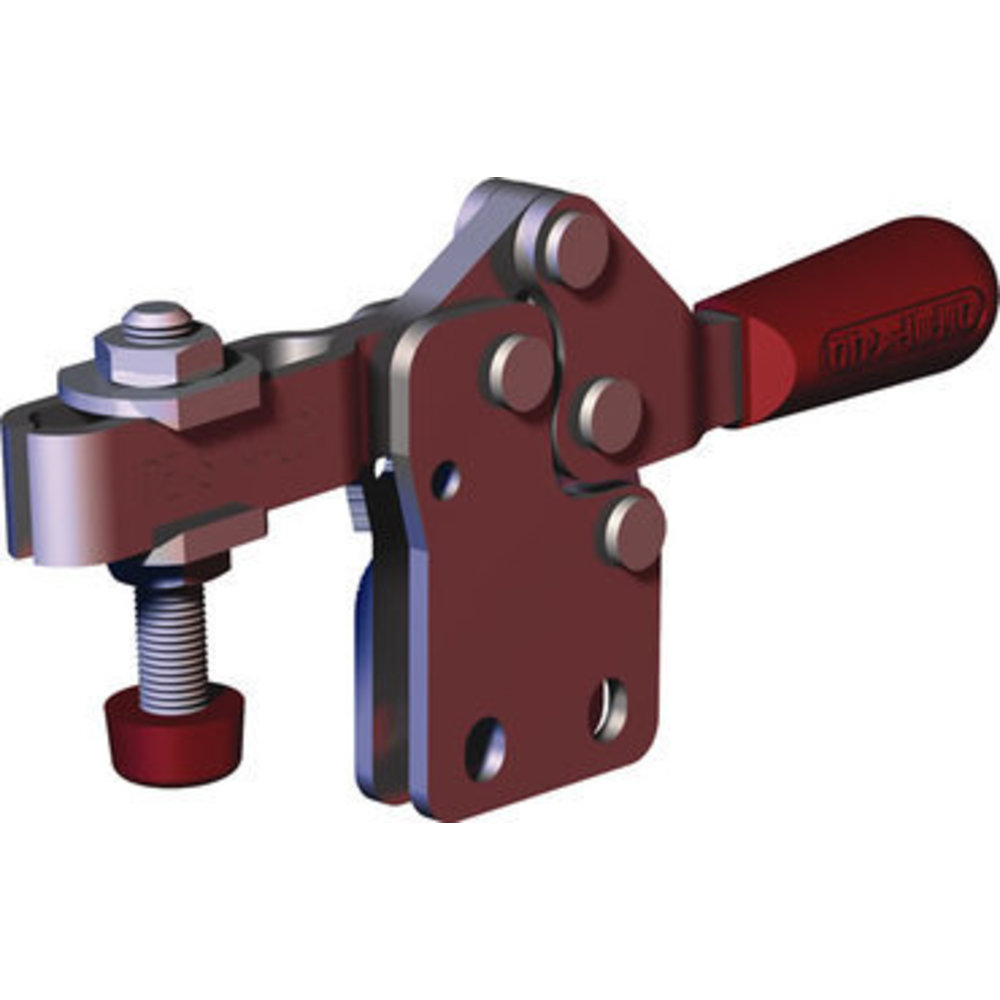

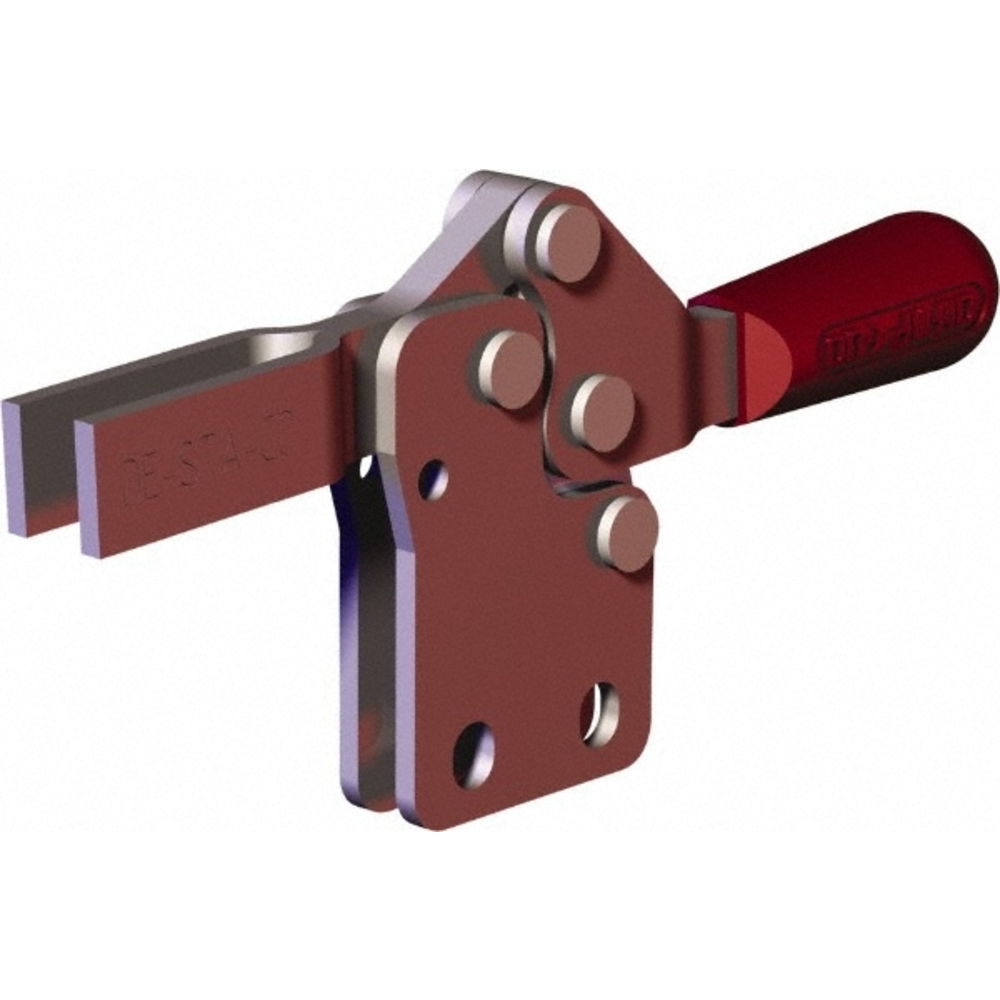

The difference lies in the positioning of the clamp handle when it is in the locked position. A vertical clamp handle is positioned vertically (perpendicular to the base) when in the locked position, while in the case of a horizontal toggle clamp, it is positioned horizontally (parallel to the base).

What is the significance of the red colour of the handle of Destaco clamps?

There is no such significance of the colour of the clamp's handle, as it only represents a recognisable area. This helps operators in finding the handle quickly & easily.

What does a clamp's holding capacity signify?

The clamp's holding capacity or holding force represents the capability to hold down mechanical equipment or sheet metal while assembling automotive parts or during manufacturing processes.

How are horizontal toggle clamps used?

Horizontal toggle clamps use an over-centre locking action to hold a workpiece or fixture in the locked position.

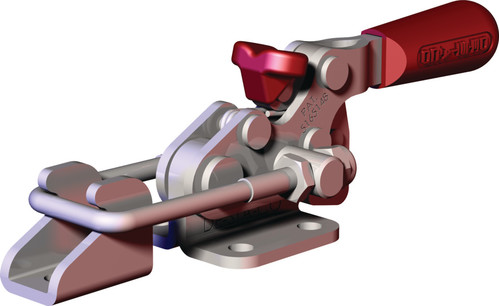

What is the Toggle Lock Plus mechanism?

Selected Destaco horizontal clamp models feature the Toggle Lock Plus mechanism to prevent accidental opening of clamps.

Which grease is ideal for Destaco clamps for their rebuilding?

A coupling grease like Mobil XTC should be used when dealing with Destaco mechanical clamps, while the Magnalube G grease is great for use with pneumatic cylinder seals.

£ GBPChange Country

£ GBPChange Country